Engine braking slows your motorcycle using internal engine resistance and vacuum, not your brake pads.

When you close the throttle while in gear, the pistons pull against a vacuum in the intake manifold, creating drag that slows the crankshaft and rear wheel. This deceleration happens naturally on every bike, and the effect strengthens when you downshift to lower gears at the right RPM.

Last week, I stumbled across a post from a new rider on Reddit who described it better than I ever could:

“One of the biggest notable differences I’ve felt … engine braking substantially slows down the bike. To the point where I don’t really use the brakes unless I’m coming to a clearly anticipated stop.” Reddit

Modern riders use engine braking to reduce brake wear, maintain control on descents, and position themselves in the proper gear for corners. This isn’t just for racers, it’s a fundamental skill that makes you safer and more connected to your bike.

Let’s break down exactly what happens inside your engine and how to use this technique correctly.

🎯 Key Takeaways

- What It Is: Engine braking slows your bike using internal engine vacuum and resistance when you close the throttle, not your brake pads.

- Why Use It: It saves money on brake wear, prevents overheating on downhill slopes, and keeps you in the right power band for corners.

- The Golden Rule: Always “rev-match” (blip the throttle) when downshifting to prevent jerky stops or rear-wheel locking.

- Safety Tip: Engine braking does not turn on your brake lights. Always tap your brake lever lightly to warn drivers behind you.

- How Engine Braking Works on a Motorcycle

- Why Riders Use Engine Braking

- How to Engine Brake Correctly

- Critical Safety Considerations

- Does Engine Braking Damage Your Motorcycle?

- Engine Braking in Different Riding Scenarios

- Advanced: Slipper Clutches and Engine Braking Control

- Common Mistakes to Avoid When Engine Braking

- Troubleshooting Engine Braking Issues

- Key Takeaways for Better Engine Braking

- FAQs about Motorcycle Engine Braking

How Engine Braking Works on a Motorcycle

Engine braking transforms your engine into a speed-reduction system.

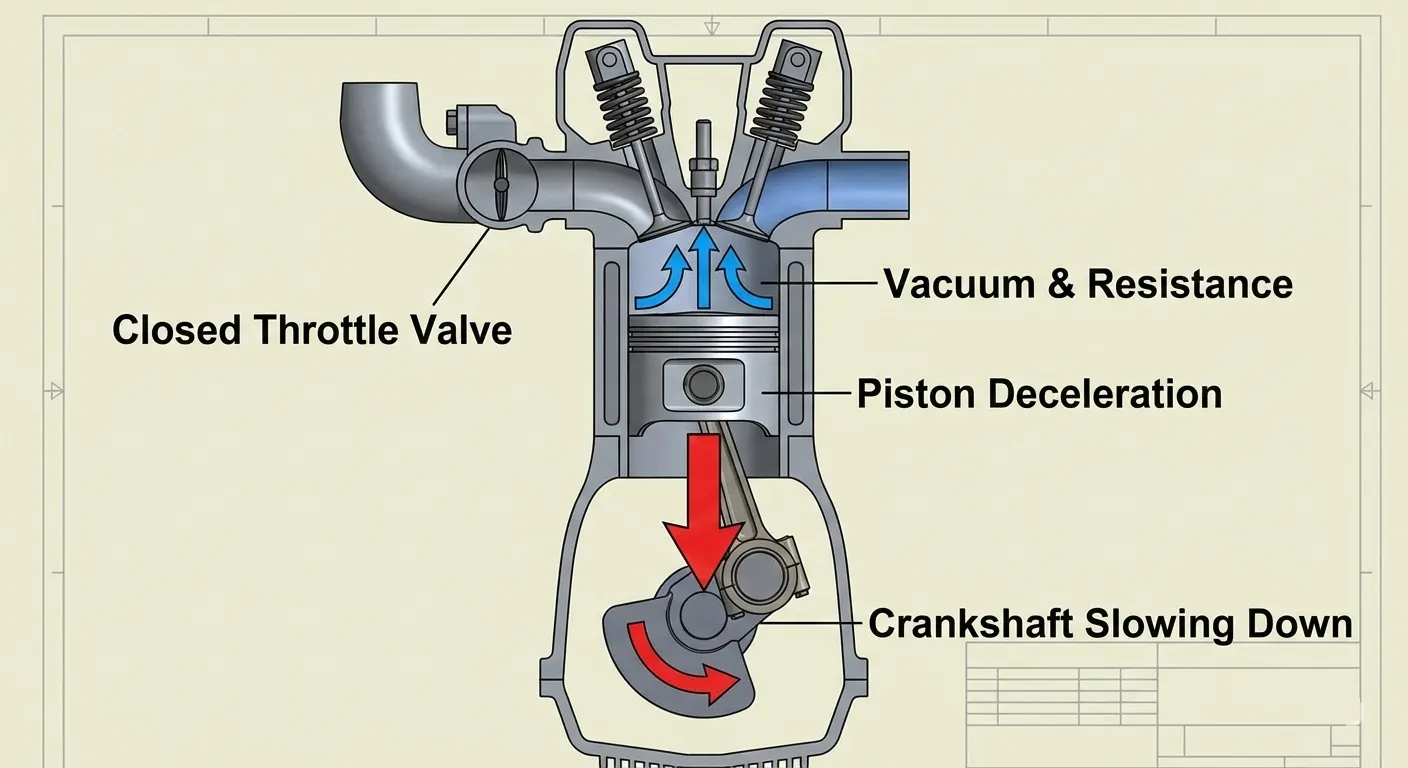

Close your throttle while riding in gear. The throttle plate shuts, blocking airflow to the cylinders. The pistons continue moving but now pull against a closed tube. This vacuum creates resistance that slows the piston movement, which slows the crankshaft, which slows your rear wheel through the drivetrain.

Think of it like breathing through a straw with your finger partially covering the end. The resistance you feel? That’s what your engine experiences when the throttle closes.

The oil pump keeps running during engine braking. Your engine stays properly lubricated. Modern fuel injection systems cut fuel delivery completely when you roll off the throttle, meaning zero fuel burns while you slow down.

Key difference by engine type: Four-stroke engines produce stronger engine braking than two-strokes due to greater internal compression and vacuum effects. If you ride a two-stroke, you’ll notice less natural deceleration when closing the throttle.

What Happens When You Downshift

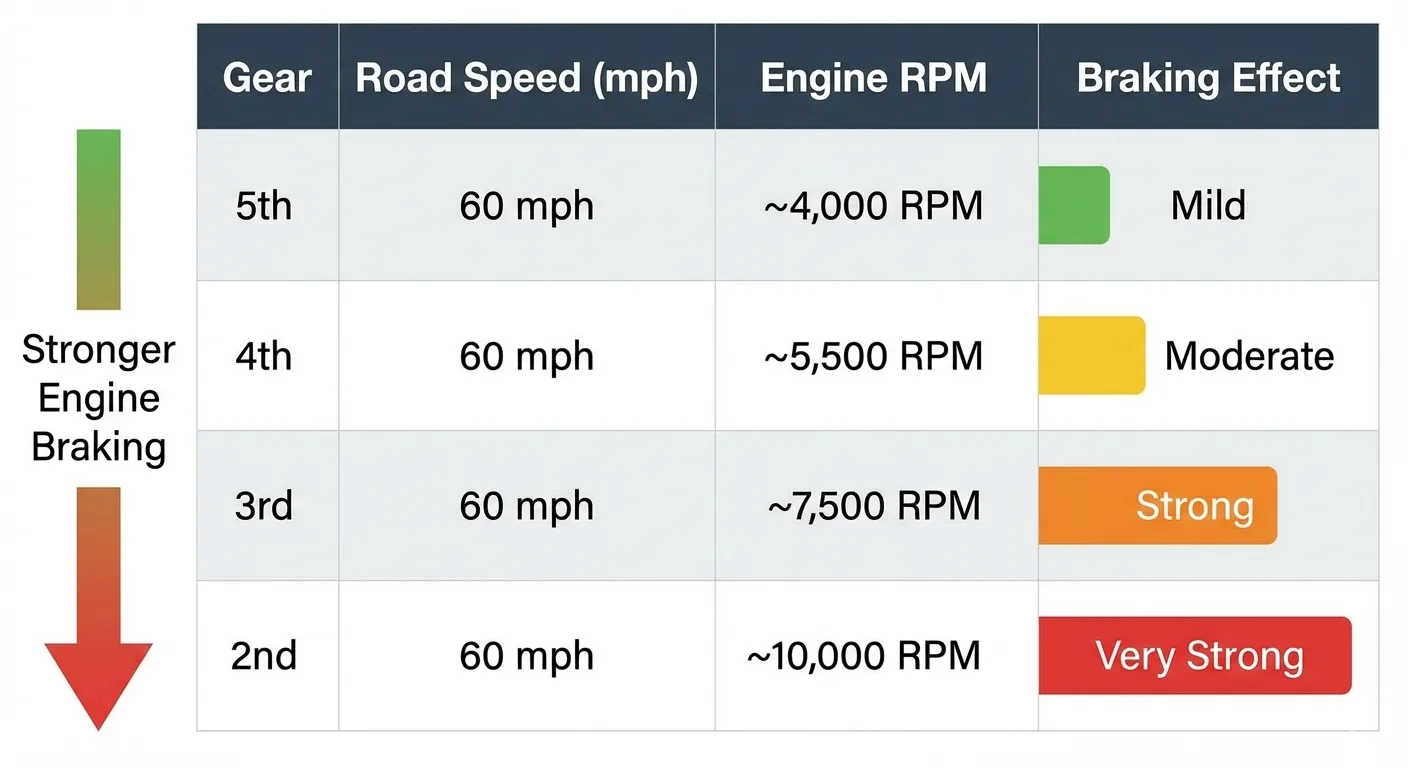

Downshifting amplifies engine braking significantly.

Higher engine RPM creates stronger vacuum and more resistance. When you shift from fifth to fourth gear at the same road speed, your engine spins faster. More piston movement against that vacuum equals more braking force at the rear wheel.

Modern sport bikes and touring motorcycles often include engine braking control systems that manage how much deceleration happens during aggressive downshifts. Some systems work with your bike’s ride modes to adjust engine braking intensity based on conditions.

Why Riders Use Engine Braking

01. Extends Brake Component Life

Your brake pads wear down from friction and heat. Engine braking does the slowing without touching the pads or discs. Over thousands of miles, this saves wear and money on brake maintenance.

Pro riders on track days can go through brake pads in a single session. They rely heavily on engine braking to preserve their braking system for when they really need maximum stopping power.

02. Prevents Brake Fade on Long Descents

Riding down mountain passes puts enormous stress on brakes. Continuous braking generates heat. Too much heat causes brake fade, when your brakes lose effectiveness because the fluid boils or pads glaze over.

Downshift to second or third gear before a long descent. Your engine holds your speed steady without riding the brakes. This keeps your brake system cool and ready for emergency stops.

03. Positions You in the Right Gear

Approaching a corner in fifth gear? You won’t have enough power to accelerate out smoothly. Engine braking while downshifting puts you in third or fourth gear, exactly where you need to be for corner exit.

This matters for safety too. If you need to accelerate away from a hazard, being in the proper gear means instant throttle response. Stay in too high a gear and your engine lugs, delaying your escape.

04. Improves Control on Slippery Surfaces

Sudden brake application on wet or icy roads can lock wheels. Engine braking slows you more gradually, reducing the risk of skidding. The deceleration comes through the drivetrain instead of sudden friction at the tire contact patch.

However, aggressive downshifts on low-traction surfaces can still lock the rear wheel. Smooth technique matters more than the method itself.

05. Saves Fuel

Modern fuel-injected motorcycles cut fuel delivery completely during engine braking. Zero fuel enters the cylinders. You’re coasting with the engine doing the work, not burning gas.

The fuel savings are small per instance, but add up over months of riding. City riders who frequently slow for traffic lights see the most benefit.

How to Engine Brake Correctly

Basic Technique

Roll off the throttle smoothly. Stay in gear. Feel your bike slow naturally. That’s engine braking at its simplest.

For stronger effect, downshift one gear. Your engine RPM rises and braking increases. Release the throttle and let the engine do its work.

Always keep your bike in an appropriate gear for your speed. Riding in too high a gear forces you to brake more when slowing. Riding in too low a gear over-revs the engine and wastes fuel.

Rev-Matching for Smooth Downshifts

Downshifting without rev-matching can cause rear wheel hop or jerky deceleration.

Rev-matching process:

- Roll off the throttle and squeeze the clutch

- Blip the throttle while pulling the clutch

- Click down one gear

- Release the clutch smoothly as RPMs match the lower gear

- Feel smooth deceleration without any jerk

The throttle blip raises engine RPM to match what the engine will spin at in the lower gear. When you release the clutch, the engine and transmission speeds match, eliminating that harsh engagement that causes the bike to lurch.

Practice this in empty parking lots before using it in traffic. Your goal: seamless gear changes that your passenger wouldn’t even notice.

Combining Brakes and Engine Braking

Professional riders use both methods simultaneously.

Approaching a turn, they:

- Apply front and rear brakes

- Downshift through gears while braking

- Rev-match each downshift

- Release brakes at turn-in point

- Exit the corner in the proper gear with engine at optimal RPM

This technique requires coordination but becomes automatic with practice. Start by separating the two: brake first, then downshift. As you improve, overlap them more until they happen together.

Two-finger braking helps: Keep your index and middle fingers on the brake lever. This leaves your other fingers free to maintain throttle control while blipping for downshifts.

Critical Safety Considerations

Your Brake Lights Don’t Activate

This is the biggest safety issue with engine braking.

The bike slows but your brake light stays off. Cars behind you don’t know you’re decelerating. In heavy traffic, this can lead to rear-end collisions.

Solution: Tap your brake lever lightly when engine braking. Just enough pressure to light up your brake light, not enough to actually brake. This alerts following traffic that you’re slowing down.

Some modern motorcycles with advanced electronics activate brake lights during strong engine braking. Check your owner’s manual to see if your bike does this. If not, always tap the brake.

Wet Road Hazards

Engine braking on slippery surfaces requires extra smoothness.

Downshift too aggressively and your rear tire can break traction. The sudden RPM increase causes the rear wheel to slow faster than the road surface allows. Result: a locked rear wheel and potential skid.

On wet, icy, or gravel roads:

- Downshift earlier and more gradually

- Skip aggressive downshifts

- Rely more on your brakes

- Keep the bike more upright when downshifting

Modern bikes with Drag-Torque Slip Control (DTSC) or similar systems help prevent rear wheel lockup during aggressive engine braking. These systems modulate engine torque delivery to match wheel speed with road speed during deceleration.

Not for Emergency Stops

Engine braking cannot stop you quickly enough in emergencies.

If a car pulls out in front of you, grab both brakes hard. Don’t waste time downshifting. Your front brake provides 70-80% of your stopping power. Use it.

Engine braking is for controlled, planned deceleration, not panic stops.

Avoid Over-Revving

Downshifting at too high a speed forces the engine past redline.

Example: You’re doing 80 mph in fifth gear. Downshift to second gear and release the clutch. Your engine screams past redline. This can damage valves, valve springs, and other internal components.

Pay attention to your tachometer. Know your bike’s safe RPM ranges for each gear. If a downshift would push you into the red zone, don’t make that shift yet. Slow down more first, or skip that gear entirely.

| Speed (mph) | Gear | Approx. RPM | Safe to Downshift? |

|---|---|---|---|

| 70 | 5th | 5,000 | → 4th ✓ |

| 70 | 4th | 7,000 | → 3rd ✓ |

| 70 | 3rd | 9,500 | → 2nd ✗ (would over-rev) |

Does Engine Braking Damage Your Motorcycle?

No, when done correctly.

Your motorcycle was designed for engine braking. The engine, clutch, and transmission can handle the forces involved. Manufacturers test these components under much harsher conditions than normal riding creates.

Common concerns debunked:

“Engine braking causes lubrication problems” → False. The oil pump runs continuously whether you’re accelerating or decelerating. Oil circulates through the engine, transmission, and clutch at all times. The throttle controls airflow and fuel, not oil pressure.

“It wears out the clutch” → False. The clutch is designed to handle full-power acceleration from a stop. The forces during engine braking are a fraction of that stress. If your clutch can handle launching the bike, it can definitely handle engine braking.

“It damages the transmission” → False. Transmission gears engage and disengage the same way whether you’re accelerating or decelerating. Proper rev-matching actually reduces stress on the transmission compared to sloppy downshifts.

What can cause damage:

- Downshifting past redline repeatedly

- Dumping the clutch during downshifts (causes shock loads)

- Lugging the engine in too high a gear

- Skipping multiple gears and releasing the clutch suddenly

Smooth, properly executed engine braking extends component life by reducing brake wear and helping you maintain better control of your motorcycle. Many motorcycle problems and fixes stem from aggressive riding habits, not from proper technique.

Engine Braking in Different Riding Scenarios

City Traffic

Stop-and-go traffic is perfect for practicing engine braking.

As traffic slows ahead, roll off the throttle and downshift one gear. The bike slows smoothly without abrupt brake application. This creates a more comfortable ride for you and your passenger.

Remember to tap your brake lever to activate your brake light. In city traffic, following vehicles are often distracted. Give them every visual cue that you’re slowing down.

Highway Riding

Engine braking is less pronounced at highway speeds in top gear.

The engine RPM is relatively low in fifth or sixth gear at 70 mph. Rolling off the throttle creates mild deceleration. For stronger effect, downshift to fourth gear, but only if traffic conditions require it.

Long rides at high RPM don’t damage modern engines, but unnecessary high-RPM cruising wastes fuel. Stay in the highest gear comfortable for your speed.

Mountain Roads and Descents

This is where engine braking shines.

Before a long downhill, shift down two gears. Second or third gear on most bikes provides enough engine braking to hold your speed at 25-35 mph without touching the brakes.

Your brake pads stay cool. Your brake fluid stays at safe temperatures. You maintain perfect control down the entire descent. At the bottom, your brakes are fresh and ready for whatever comes next.

Corner Entry

Racers combine engine braking with trail braking for precise corner speed control.

Approach the turn while braking hard. Begin downshifting while still on the brakes. Each downshift increases engine braking and helps slow the bike. By the turn-in point, you’re in the correct gear with the engine at optimal RPM for corner exit.

This technique keeps the bike stable and the suspension loaded properly. It also means instant throttle response when you apex and begin accelerating out of the turn.

Sport riders should avoid redlining the engine during aggressive downshifts. Stay below redline even when engine braking hard into corners.

Track Days and Racing

Professional riders adjust engine braking based on track conditions and tire grip.

Some corners benefit from strong engine braking to rotate the bike quickly. Other corners require minimal engine braking to maintain stability on the edge of the tire.

Modern sportbikes allow riders to adjust engine braking intensity through ride modes. Experiment with different settings to find what works for your riding style and the specific track.

Advanced: Slipper Clutches and Engine Braking Control

Slipper Clutches

Sport bikes often include slipper clutches to manage engine braking.

Traditional clutches lock the engine and rear wheel together solidly. During aggressive downshifts, this can cause the rear wheel to hop or chatter as the engine forces it to slow down faster than traction allows.

Slipper clutches partially disengage during engine braking. If the rear wheel tries to drive the engine faster than the engine wants to spin, the clutch slips slightly. This prevents rear wheel lockup during hard downshifts.

Riders with slipper clutches can downshift more aggressively without upsetting the chassis. This is why MotoGP bikes and serious track machines use them. They allow later, harder braking with less risk of rear wheel instability.

Electronic Engine Braking Control

Modern bikes from manufacturers like Ducati, BMW, and KTM include electronic engine braking control.

These systems adjust throttle butterfly position, ignition timing, and fuel delivery during deceleration. Riders can select different levels of engine braking through ride mode settings:

- High engine braking: Strong deceleration, helps rotate the bike in corners

- Medium engine braking: Balanced for street riding

- Low engine braking: Minimal deceleration, more like a two-stroke feel

These systems work with traction control and ABS to optimize braking performance. They’re especially helpful in wet conditions where aggressive engine braking might otherwise lock the rear wheel.

Common Mistakes to Avoid When Engine Braking

Downshifting Too Many Gears at Once

Never downshift from fifth to second in one clutch pull.

Your engine can’t match that RPM jump. When you release the clutch, the rear wheel either locks up or the bike lurches violently forward. Both scenarios can cause a crash.

Downshift one gear at a time. Let the clutch out between each shift. This gives the engine time to adjust to the new RPM range.

Holding the Clutch In During Braking

Pulling the clutch and coasting eliminates all engine braking benefits.

Your engine disconnects from the rear wheel. The bike rolls freely like a bicycle. You lose that third braking force that helps control your speed.

Worse, if you need to accelerate suddenly to avoid a hazard, you’re stuck in the wrong gear with the clutch pulled in. By the time you downshift and release the clutch, the hazard already hit you.

Keep the clutch out unless you’re actively shifting. Stay connected to your engine.

Ignoring Engine Sound and Feel

Your engine tells you when you’re in the wrong gear.

Too low an RPM and the engine sounds labored. It vibrates more. Throttle response feels sluggish. You’re lugging the engine, riding in too high a gear for your speed.

Too high an RPM and the engine screams. It feels frantic. You’re over-revving—riding in too low a gear for your speed.

Learn your bike’s happy RPM range. Most engines work best between 3,000-8,000 RPM depending on engine displacement and type. Stay in that range and both acceleration and engine braking work optimally.

Not Practicing in Safe Environments

Engine braking combined with downshifting requires muscle memory.

Don’t learn in rush-hour traffic or on mountain roads with steep dropoffs. Find an empty parking lot or quiet residential street. Practice downshifting through all your gears repeatedly until the movements become automatic.

Your goal: downshift without thinking about it. The proper technique should feel natural before you use it in challenging situations.

Troubleshooting Engine Braking Issues

Engine Cuts Out During Deceleration

If your engine keeps cutting out when you close the throttle or downshift, you likely have a carburetor or fuel injection issue.

Common causes:

- Idle speed set too low

- Pilot jet clogged (carbureted bikes)

- Intake manifold vacuum leak

- Faulty throttle position sensor (fuel-injected bikes)

This isn’t normal engine braking behavior. Get it checked by a mechanic.

Bike Stalls When Downshifting

Some riders experience engine dying when throttle applied or during deceleration.

If your bike stalls specifically during downshifts, check:

- Clutch adjustment (too tight can cause stalling)

- Idle RPM setting

- Battery voltage (weak battery affects fuel injection)

Excessive Engine Braking

If your bike decelerates too aggressively when you close the throttle, even in high gears, you might have:

- Overly restrictive exhaust (creates high back-pressure)

- Vacuum leak causing lean running

- Engine braking control system malfunction

Different motorcycle engine types produce different levels of engine braking. V-twins typically have stronger engine braking than inline-fours due to their firing order and design.

Jerky Downshifts

If your downshifts feel harsh even when rev-matching, consider:

- Clutch cable adjustment (too much free play)

- Worn clutch plates (causes grabby engagement)

- Transmission oil needs changing

Smooth downshifts require properly maintained components. Don’t ignore maintenance hoping technique alone will fix mechanical issues.

Key Takeaways for Better Engine Braking

Master these fundamentals:

Always stay in the appropriate gear for your speed. This makes engine braking available whenever you need it without fumbling through multiple downshifts.

Rev-match your downshifts. Blip the throttle as you downshift. This matches engine speed to wheel speed and eliminates jerky transitions.

Tap your brake to activate your brake light. Following traffic needs to know you’re slowing down. Don’t rely on engine braking invisibly.

Practice smooth clutch control. Ease the clutch out after downshifting. Dumping it causes harsh engagement and upsets the bike’s balance.

Combine engine braking with your regular brakes. Use both systems together. They complement each other and give you maximum control.

Stay aware of road conditions. Wet, icy, or gravel surfaces require gentler technique. Aggressive downshifts can lock the rear wheel when traction is limited.

Know your limits. Emergency stops require hard braking, not engine braking. Use the right technique for the situation.

Understanding your motorcycle’s engine cut-off switch and other safety controls helps you maintain better overall control when combining engine braking with other techniques.

FAQs about Motorcycle Engine Braking

Does engine braking work in neutral?

No. In neutral, the engine disconnects from the drivetrain. Rolling off the throttle in neutral provides zero engine braking because the engine isn’t connected to the wheels.

Can engine braking damage the clutch or transmission?

Not when done correctly. Modern motorcycle clutches and transmissions handle engine braking forces easily. Over-revving from downshifting too early can cause damage, but proper technique is perfectly safe.

Should I engine brake in the rain?

Yes, but more gently. Smooth engine braking on wet roads helps control speed without aggressive brake application. Avoid sudden downshifts that might lock the rear wheel on slippery surfaces.

Why is engine braking stronger on some motorcycles?

Four-stroke engines create more vacuum and compression than two-strokes, producing stronger engine braking. Engine displacement, compression ratio, and valve timing also affect intensity.

Do I need to blip the throttle when downshifting?

For smooth downshifts, yes. Rev-matching by blipping the throttle prevents jerky engagement when releasing the clutch. It’s especially important at higher speeds and during aggressive riding.

Can engine braking save fuel?

Yes. Modern fuel-injected bikes cut fuel delivery completely during engine braking. Over time, using engine braking instead of coasting in neutral saves measurable fuel.

Is it bad to downshift while braking?

No, it’s actually recommended. Professional riders downshift while braking to position themselves in the correct gear and add engine braking to their overall deceleration.

How do I know what gear to be in?

Listen to your engine. It should sound comfortable, not labored or screaming. Most engines work best between 3,000-8,000 RPM for street riding.