Your bike cranks but won’t fire. You twist the key, press the starter, but still nothing. Before you call a tow truck, check one thing: that small red switch on your right handlebar.

The motorcycle engine cut-off switch (kill switch) instantly stops your engine by interrupting power to the ignition coil, preventing spark plugs from firing.

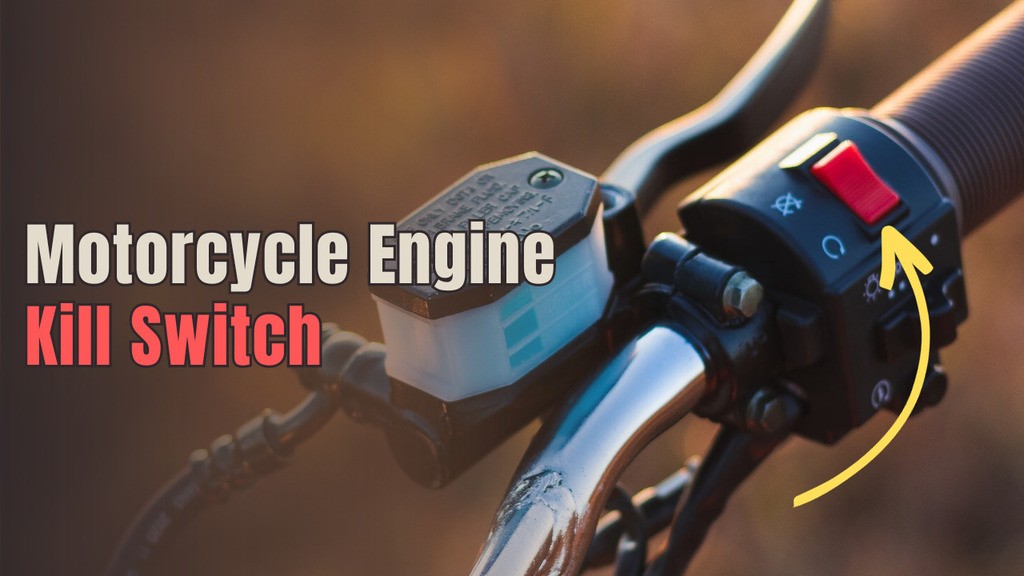

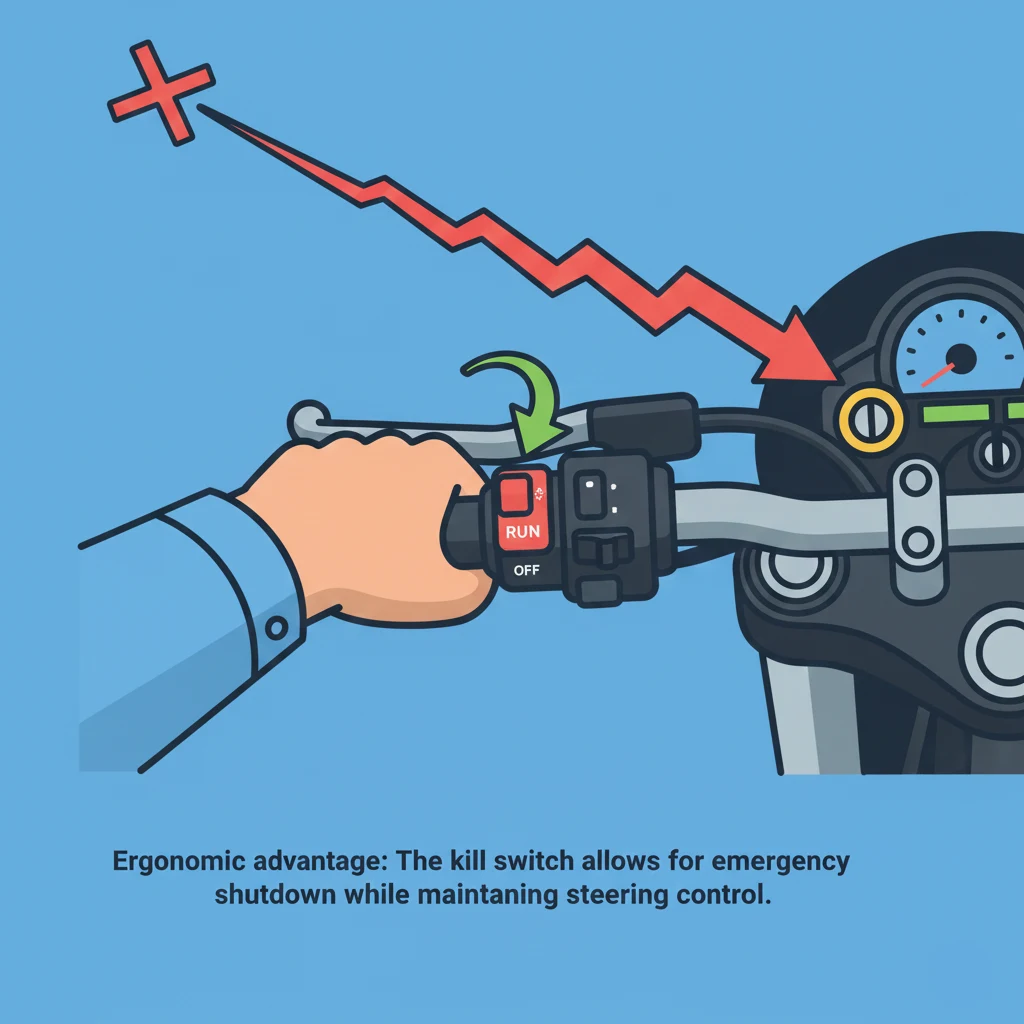

Located on the right handlebar within thumb’s reach, this red switch cuts the engine in under one second without requiring you to release the handlebars. Most no-start issues stem from accidentally leaving this switch in the “off” position, which blocks all ignition signals even when the key is turned on and the battery is fully charged.

The kill switch solves one critical problem: rapid engine shutdown during emergencies. But it creates another when riders forget its position. This guide eliminates both issues.

🎯 Key Takeaways

- The Primary Function: Instantly stops the engine by cutting power to the ignition coils (stops the spark).

- The “No-Start” Culprit: Most “dead” bikes are simply left in the OFF position. Always check the red switch first.

- Emergency Tool: Use it for stuck throttles, post-crash shutdowns, or fire hazards—it allows you to kill the engine without moving your hands from the bars.

- The Golden Rule: Use the kill switch to stop the engine, but always turn the key to “Off” afterward to prevent battery drain.

- What the Kill Switch Actually Does

- Where to Find Your Kill Switch

- When Your Kill Switch Becomes a Problem

- Emergency Situations Where You Need It

- The Right Way to Shut Down Your Engine

- Testing Your Kill Switch Function

- Common Kill Switch Problems and Fixes

- Kill Switch vs. Ignition Key: What’s the Difference?

- Links Between Kill Switch and Other Engine Issues

- Maintenance Schedule

- Additional Safety Features Connected to Kill Switches

- What About Engine Braking?

- FAQs About Motorcycle Engine Cut Off Switch

What the Kill Switch Actually Does

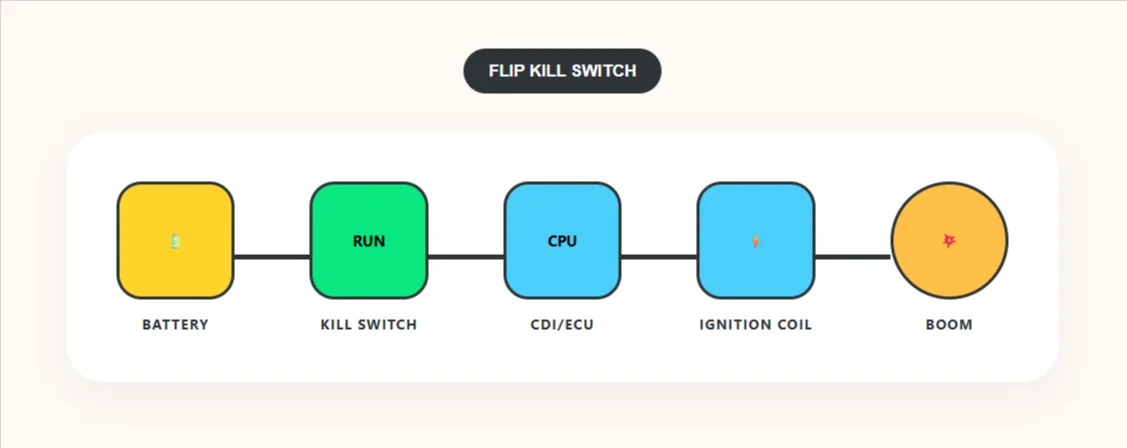

The kill switch breaks the electrical circuit between your battery and ignition coil.

When you flip it to “off,” the ignition coil receives no power. No power means no high-voltage spark. No spark means the fuel-air mixture in your cylinders never ignites. Your engine stops immediately.

Think of it as cutting the spark plug’s power supply at the source. Modern bikes use a Capacitor Discharge Ignition (CDI) unit that transforms 12-volt battery power into 20,000+ volts for the spark plugs. The kill switch sits upstream of this entire chain. Flip it off, and the CDI never receives the initial voltage it needs to create that massive spark.

| Component | Function | Kill Switch Effect |

|---|---|---|

| Battery | Supplies 12V power | Still active |

| Kill Switch | Controls circuit flow | Breaks connection |

| Ignition Coil/CDI | Boosts voltage to 20,000V+ | Receives no power |

| Spark Plug | Creates ignition spark | Cannot fire |

The beauty lies in its simplicity. Unlike complex computer-controlled systems, the kill switch operates through basic electrical principles. One circuit break stops everything.

Where to Find Your Kill Switch

The kill switch sits on the right handlebar cluster, positioned for your thumb. Look for these identifying features:

- Red coloring (sometimes with white text)

- Run/Off markings or similar labels

- Rocker or toggle design that flips up and down

- Integration with starter button on newer bikes

Standard placement puts it directly above or next to the electric starter button. This positioning allows emergency shutdowns without removing your hand from the throttle.

Different manufacturers use slight variations:

- Sport bikes: Often combined with starter and engine mode controls

- Cruisers: Separate toggle switch with clear on/off positions

- Dual-sport bikes: Waterproof sealed design for off-road durability

If you cannot locate yours, check your owner’s manual’s diagram of handlebar controls.

When Your Kill Switch Becomes a Problem

The kill switch causes three main issues:

1. Forgotten “Off” Position

You park your bike and flip the kill switch. Later, you return and the bike won’t start. The battery shows 12.6 volts. The fuel pump primes. Nothing happens when you press the starter.

The kill switch remains in “off” position. Your starter motor engages (you hear it spinning), but the engine never fires because the ignition coil receives no signal.

Emergency stop buttons can be easily engaged with one hand, making it relatively common to leave them on accidentally.

2. Stuck or Corroded Contacts

Rain, dirt, and repeated use wear down the internal contacts. The switch feels normal but fails to complete the circuit when flipped to “run.”

Signs of contact problems:

- Engine dies randomly while riding

- Intermittent no-start conditions

- Engine fires briefly then cuts out

- Clicking sound when operating the switch

Dust and moisture can jam your kill switch, preventing proper contact closure.

3. Confusion with Other No-Start Causes

Riders blame the battery, starter motor, or fuel system when the actual culprit sits in plain sight. This leads to unnecessary repairs and diagnostic costs.

The kill switch eliminates spark entirely. If your engine keeps cutting out during normal riding, first verify the kill switch maintains solid contact in the “run” position before investigating complex electrical faults.

Emergency Situations Where You Need It

The kill switch earns its name during these scenarios:

Stuck Throttle Cable

Your throttle grip jams open. The engine screams to redline. You pull the clutch but need to stop the motor immediately.

One thumb press kills the engine while your other hand maintains steering control. Reaching for the ignition key requires releasing the handlebars, dangerous at speed.

Post-Crash Engine Shutdown

You go down. The bike slides across pavement, still running. A spinning rear wheel can rip clothing or cause burns. Fuel leaks onto hot engine components.

Emergency services are trained to locate the bright red button when attending an accident.

Bystanders can safely kill the engine without understanding your bike’s ignition system.

Fire Prevention

Fuel sprays from a ruptured line onto the exhaust. Every second counts. The kill switch stops combustion instantly, eliminating the ignition source.

Standard procedure: kill switch first, then the ignition key, then the fuel valve if accessible.

Theft Deterrence

Hidden aftermarket kill switches prevent hotwiring. Even if thieves bypass your ignition lock, the engine won’t start without completing this additional circuit.

Some riders install secondary kill switches in concealed locations as a security layer beyond steering locks and disc brakes.

The Right Way to Shut Down Your Engine

Follow this sequence every time you park:

- Pull the clutch lever fully (disengages transmission)

- Press the kill switch (stops combustion immediately)

- Turn the ignition key to “off” (cuts all electrical power)

- Remove the key (secures the bike)

Why this order matters: The clutch prevents the bike from lurching forward. The kill switch stops the engine quickly without stalling against compression. The ignition key removes residual battery drain from dashboard lights and accessories.

Many riders reverse steps 2 and 3, which works fine. The critical error involves forgetting step 3 entirely, leaving the ignition “on” drains your battery even though the engine sits silent.

What NOT to Do

Never pulse the kill switch repeatedly. One press suffices. Multiple taps stress the electrical contacts and provide no benefit.

Never use it to control idle speed. Blipping the engine on and off with the kill switch creates incomplete combustion that fouls spark plugs.

Never flip it while moving at speed. Engine braking disappears instantly. Your bike becomes a 400-pound coasting object with no power and potentially locked drive wheels.

The only exception: genuine emergencies that require immediate shutdown.

Testing Your Kill Switch Function

Perform this monthly check:

Basic Operation Test

- Start your engine

- Let it idle in neutral

- Flip the kill switch to “off”

- Engine should die within one second

- Flip back to “run”

- Restart the engine normally

If the engine continues running after hitting the switch, you have a wiring fault or failed switch mechanism requiring immediate repair.

Contact Inspection

- Turn ignition off, remove key

- Inspect switch housing for cracks or moisture

- Press the switch several times, and feel for smooth, positive clicks

- Look for corrosion around switch edges

- Test for loose mounting screws

Loose switches indicate handlebar crash damage or worn mounting points.

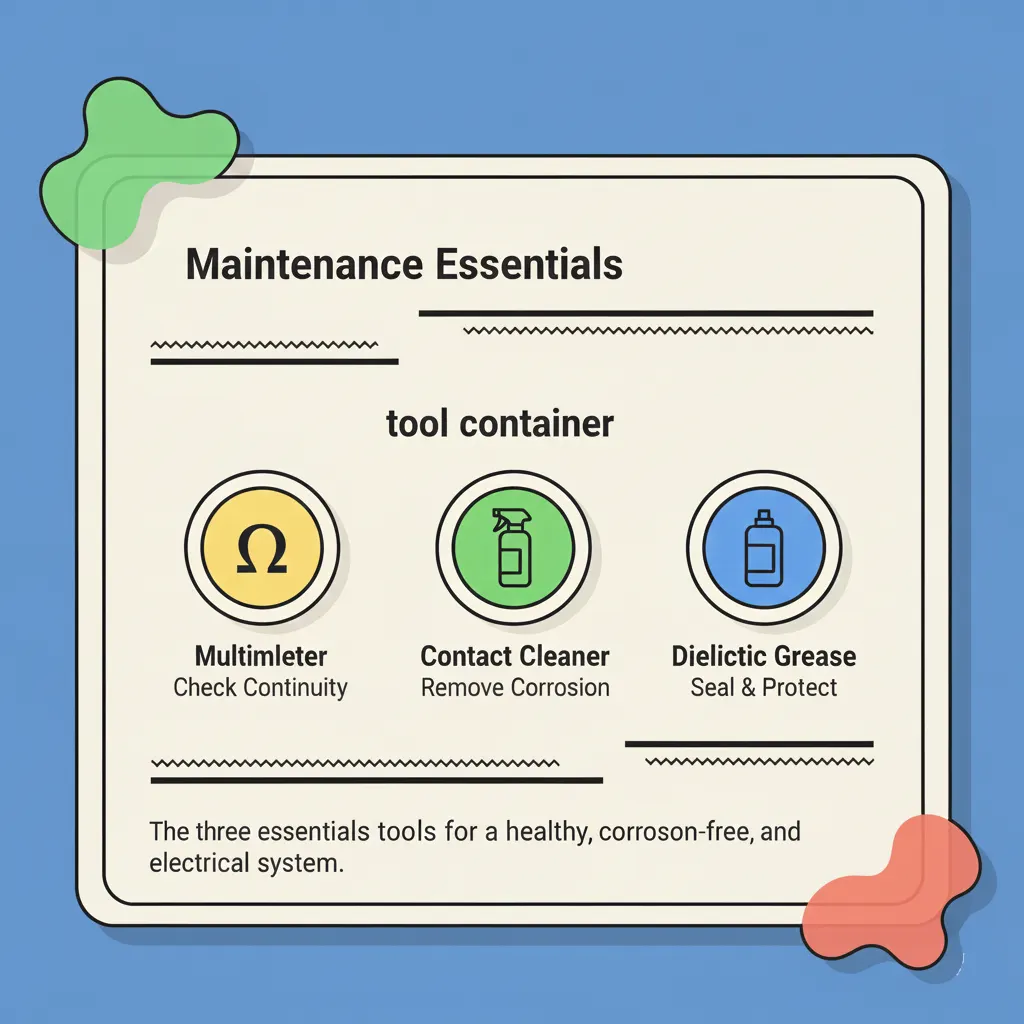

Electrical Continuity Check (requires multimeter)

- Set multimeter to resistance (ohms) mode

- Disconnect kill switch wiring harness

- Switch to “off” — meter reads near zero ohms (closed circuit)

- Switch to “run” — meter reads infinite resistance (open circuit)

If readings don’t change between positions, the internal contacts have failed.

Common Kill Switch Problems and Fixes

| Problem | Symptom | Solution |

|---|---|---|

| Forgotten position | Engine won’t start, battery good | Check switch position before other diagnosis |

| Corroded contacts | Intermittent running, random stalling | Clean with electrical contact cleaner |

| Broken spring | Switch won’t stay in position | Replace entire switch assembly |

| Water intrusion | Fails in rain | Apply dielectric grease to contacts |

| Loose wiring | Engine cuts out over bumps | Secure connector with zip ties |

Most problems resolve with contact cleaning. Remove the switch housing, spray electrical contact cleaner on the internal mechanism, and work the switch 20-30 times to break up corrosion.

If cleaning fails, replacement switches cost $15-40 for most models. Installation takes 30 minutes with basic tools.

When Kill Switch Failure Means “Won’t Turn Off”

Some riders report the engine continuing to run even after hitting the kill switch and turning the key off.

This dangerous condition suggests:

- Short circuit bypassing the kill switch

- Stator or voltage regulator failure flooding the system

- Welded switch contacts stuck in “run” position

Emergency solution: Pull the spark plug cap to eliminate ignition. Long-term: inspect the entire charging system for positive voltage faults.

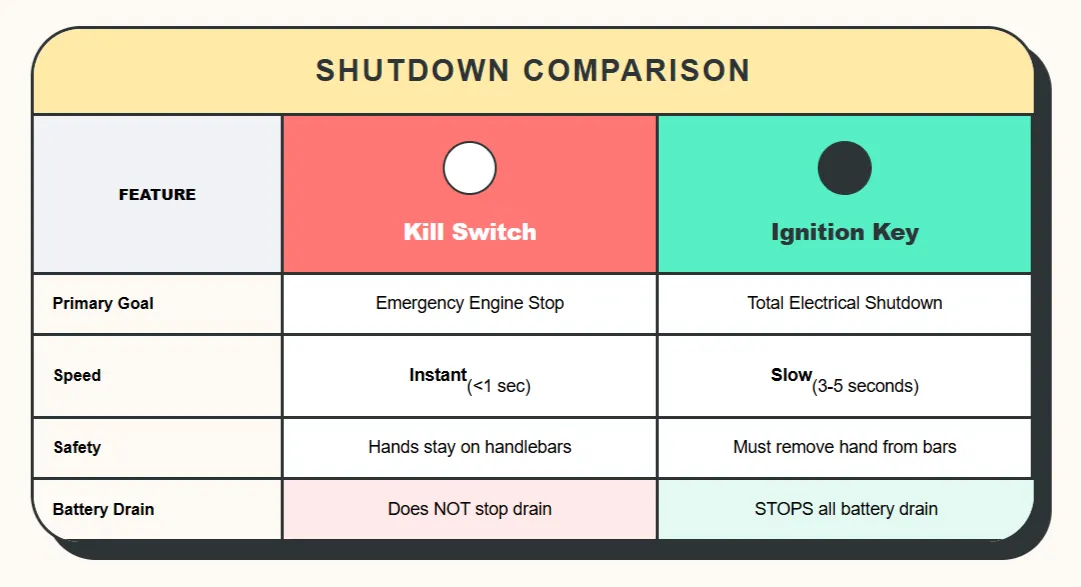

Kill Switch vs. Ignition Key: What’s the Difference?

Many riders wonder why bikes need both mechanisms.

Kill Switch

- Cuts power to ignition coil only

- Leaves lights, fuel pump, and accessories powered

- Accessible without removing hands from bars

- Response time: under 1 second

Ignition Key

- Disconnects entire electrical system

- Prevents battery drain from all components

- Requires hand movement away from controls

- Response time: 3-5 seconds

The ignition key provides complete electrical shutdown. The kill switch provides emergency speed.

Using only the kill switch to “park” your bike leaves the ignition system powered on. Dashboard lights, fuel pump, and control modules continue drawing current. A fully charged battery can drain flat in 48-72 hours this way.

Always use both. Kill switch for fast engine stop, ignition key for full system shutdown.

Links Between Kill Switch and Other Engine Issues

The kill switch intersects with several engine problems:

Intermittent Power Loss: If your bike suffers from engine cutting out randomly, the kill switch wiring harness might be shorting intermittently. Vibration loosens connectors, creating momentary opens in the circuit.

Throttle Response Problems: When the engine dies as you apply throttle, riders often suspect fuel delivery. But a kill switch with failing contacts can create micro-disconnections under vibration load, mimicking fuel starvation symptoms.

Hot-Start Difficulties: Bikes that won’t start when the engine is hot sometimes have kill switches with heat-sensitive internal components. The switch works perfectly cold but fails to maintain contact after engine heat soaks through the handlebars.

Electrical System Context: Different motorcycle engine types integrate kill switches differently. Single-cylinder thumpers use simple grounding systems. Multi-cylinder sport bikes route the kill switch through computerized ECUs that require specific voltage signals.

Understanding these connections helps diagnose complex issues. If you experience unusual engine noise during acceleration along with intermittent power loss, check the kill switch before assuming mechanical failure.

The kill switch might seem like a minor component, but it sits at the heart of your ignition circuit. Problems here radiate outward, creating symptoms that mimic dozens of other failures.

Maintenance Schedule

Incorporate kill switch inspection into regular service:

Monthly:

- Visual inspection for damage or corrosion

- Function test with engine running

- Check mounting security

Every 6 Months:

- Clean contacts with electrical spray

- Apply dielectric grease to connector

- Test resistance with multimeter

Annually:

- Verify wiring harness has no chafing

- Inspect for water intrusion in switch housing

- Replace if operation feels mushy or inconsistent

Riders in wet climates or those who regularly ride off-road should double this frequency.

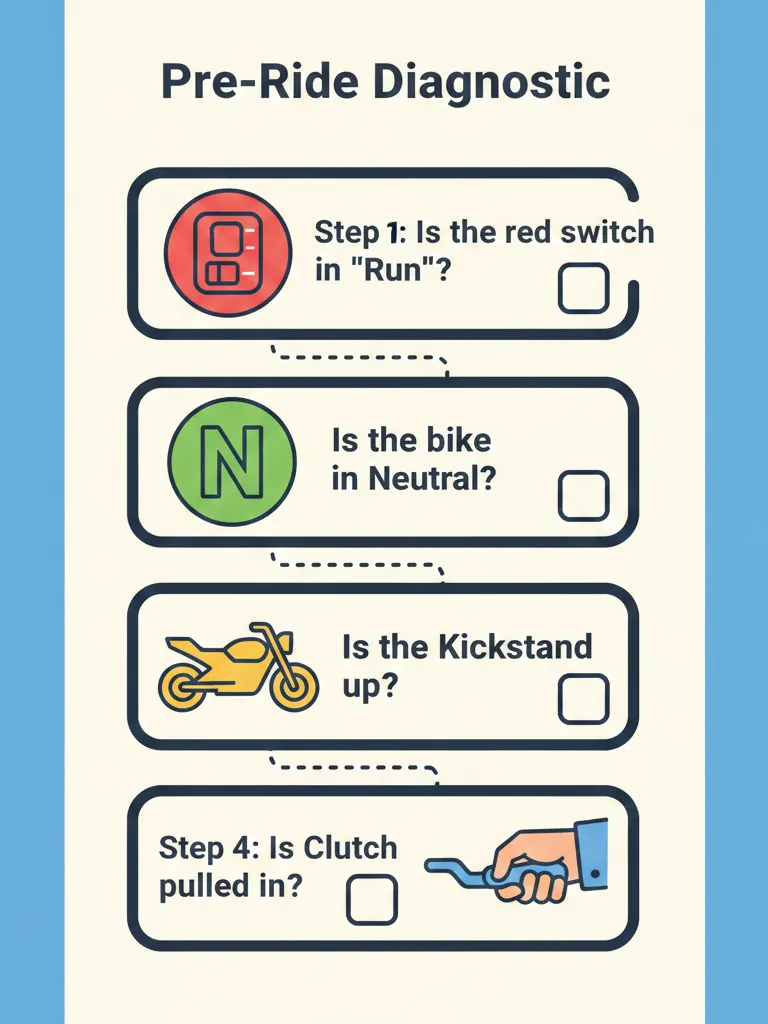

Additional Safety Features Connected to Kill Switches

Modern motorcycles layer multiple safety cutoffs:

Kickstand Switch: Prevents starting or riding with the stand down. Works in parallel with the kill switch, either one interrupts the ignition circuit.

When the kickstand is down, it opens the circuit, and when up, it closes the circuit.

Clutch Safety Switch: Requires clutch engagement before the starter motor engages. Some models won’t start at all without clutch input, even in neutral.

Tip-Over Sensor: Cuts ignition if the bike falls beyond a certain angle. Prevents runaway bikes and fire hazards after crashes.

These systems work together. Understanding how they interact prevents diagnostic confusion when troubleshooting no-start conditions.

For a comprehensive overview of common starting problems and solutions, see motorcycle problems and fixes.

What About Engine Braking?

Engine braking effect continues even after using the kill switch.

When you cut ignition, combustion stops but mechanical compression remains. The pistons still compress air on their upstrokes, creating resistance that slows the bike.

This resistance provides limited braking force. However, it’s significantly weaker than engine braking with a running motor. Plan for longer stopping distances after emergency kill switch activation.

Never rely on post-cutoff engine braking as your primary deceleration method. Use it only as supplemental resistance while applying your brake lever and pedal.

FAQs About Motorcycle Engine Cut Off Switch

Is it bad to use the kill switch to stop my motorcycle?

No, it is not mechanically harmful. Manufacturers design the switch to cut the ignition safely. However, always remember to turn the key to the “off” position afterward to prevent draining your battery.

Can a kill switch malfunction?

Yes, internal contacts corrode or break over time. Signs include difficulty shutting off the engine or random stalling. Have a mechanic inspect it if you notice inconsistent operation.

Does the kill switch work if my battery dies?

No, the kill switch requires battery power to operate the ignition circuit. With a dead battery, the switch cannot interrupt a circuit that’s already unpowered.

Will a kill switch work on electric motorcycles?

Most electric motorcycles include kill switches that cut power to the motor controller. They function identically to gas bike switches despite different underlying technology.

Does engine braking work after using the kill switch?

Yes, compression braking continues even without combustion. The effect is weaker than normal engine braking but provides supplemental deceleration while coasting.

Does the kill switch function without the ignition key on?

No, the kill switch interrupts the ignition circuit only when that circuit is powered. If the key is off, there’s no circuit to interrupt.

Should I use the kill switch every time I park?

Use it as part of your shutdown sequence, but always follow it with the ignition key. The kill switch alone leaves electrical accessories drawing battery power.

Can I damage my engine by using the kill switch while riding?

Using it briefly won’t damage the engine mechanically. However, cutting power at high speed eliminates engine braking and control, creating a safety hazard.

How do I know if my kill switch has failed?

If the engine continues running after you flip the switch to “off,” or if the bike won’t start despite the switch being in “run,” the switch has failed.