Hearing the roar of a motorcycle engine can be delightful for any rider. But have you noticed unusual noises instead of the usual roar?

These noises, like clunking or tapping, could indicate problems. If you’ve experienced strange rattles or knocks when accelerating, you’re not alone.

We’ll explain what motorcycle engine noises during acceleration mean, when to worry, and how to prevent them.

Key Takeaways

- Common acceleration noises like ticking, knocking, chain noise and their causes.

- Prevent noise with proper fuel grade, warm-ups, avoiding stress on engine.

- Potential damage from unaddressed noise like wear, pollution, costly repairs.

- Inspect high-mileage components regularly to catch issues early.

- Address overheating or detonation right away to prevent engine damage.

- Monitoring unusual noises can help diagnose small problems before they worsen.

The Common Engine Noises and Their Causes and Fixes

Let’s find out what the common engine noises are, what causes them, and the possible ways to fix them:

| Noise | Cause | What Happens When the Problem Occurs | Risks of Ignoring the Problem | Prevention and Maintenance |

|---|---|---|---|---|

| Ticking | – Loose valves – Worn valve guide seals – Slacking valve train components | – Distinctive ticking sound, more noticeable at idle/low RPM – Potential performance issues in severe cases | – Increased valve train wear – Burnt valves – Engine damage | – Regular valve adjustments and inspections – Use high-quality engine oil – Replace worn valve guide seals |

| Knocking | – Worn crankshaft bearings – Cracked rod bearings | – Loud metallic knocking sound, throughout RPM range, worse under load – Performance loss – Other potential symptoms (vibrations, difficulty starting, misfires) | – Catastrophic engine failure – Increased engine damage – Safety hazard | – Immediate attention from a qualified mechanic required |

| Clattering/ Slapping | – Worn cam chain | – Distinctive clattering/slapping sound, more noticeable at idle/low RPM – Potential performance issues in severe cases | – Increased chain wear and damage – Valve timing issues – Engine damage | – Regular cam chain tension check and replacement when needed – Follow manufacturer’s service schedule |

| Detonation (Pinging) | – Low octane fuel – Excessive heat (lean mixture, engine modifications) – Incorrect ignition timing | – High-pitched metallic pinging sound, worse under acceleration – Potential performance loss | – Piston damage – Spark plug damage – Premature engine wear (valves, cylinder head) | – Use recommended octane fuel – Address lean mixtures and engine modifications – Inspect and replace faulty ignition components – Regular maintenance (spark plugs, air filter, fuel system) |

1. Ticking Sound

If your bike starts making a rhythmic tick-tick-tick when you twist the throttle, those valves may be acting up.

Causes

There are three main culprits behind a ticking sound in your motorcycle engine:

i. Loose valves: Over time, the constant opening and closing of the valves can cause wear and tear on the components responsible for maintaining the proper clearance between the valve stem and the camshaft.

This increased clearance allows the valves to “tap” against the cylinder head with each rotation, creating the ticking sound.

ii. Worn valve guide seals: These seals are located around the valve stem and act as a barrier, preventing engine oil from leaking down into the combustion chamber1.

Worn-out seals lose their effectiveness, allowing oil to seep down and temporarily “stick” the valve to its guide.

This sticking can disrupt the smooth opening and closing of the valve, causing a ticking sound as the valve tries to overcome the resistance.

iii. Slacking valve train components: The valve train is a complex system of components responsible for operating the valves.

Wear and tear on any of these components, such as rocker arms, tappets, or pushrods, can introduce unwanted slack within the system.

This slack can manifest as a ticking sound as components come into contact with each other due to the increased play.

What Happens When the Problem Occurs

- Distinctive Noise: The most common symptom is a rhythmic ticking sound, often described as a rapid “tick-tick-tick” or “click-clack-click” noise. This sound is usually more noticeable at idle or low RPMs when other engine noises are less prominent.

- Performance Issues (Potential): In severe cases, a neglected ticking sound can lead to performance problems like reduced power or hesitation during acceleration. This occurs because significant valve clearance or sticking valves can disrupt the optimal timing and efficiency of the engine cycle.

Risks of Ignoring the Problem

Leaving a ticking sound unaddressed can lead to several potential problems:

Increased Valve Train Wear: The constant tapping of loose valves against the cylinder head can accelerate wear and tear on both components. The result could be even larger clearances and more pronounced ticking in the future.

Burnt Valves: In extreme cases of neglected valve sticking due to worn guide seals, the valve might remain slightly open during combustion. It exposes the valve to excessive heat and exhaust gases, potentially leading to warping or burning of the valve seat and face.

Engine Damage: If valve clearances become too large or valves become permanently stuck, it can lead to severe engine damage. This could involve bent or broken valves, damaged pistons or cylinder head, and potentially engine failure.

Prevention and Maintenance

Regular valve adjustments and inspections according to the manufacturer’s recommended schedule are crucial to prevent ticking sounds and potential engine damage.

Additionally, using high-quality engine oil and replacing worn valve guide seals when necessary can help maintain optimal valve train performance and minimize the risk of ticking sounds.

2. Knocking Sound

When it happens, you hear a heavy diesel-like knock coming from deep in the engine.

Causes

A knocking sound in your motorcycle engine is a serious symptom that indicates significant internal damage, primarily involving two critical components:

i. Worn crankshaft bearings: These bearings are located at both ends of the crankshaft, acting as the foundation for its smooth rotation.

Over time, wear and tear can cause these bearings to lose their effectiveness, allowing the crankshaft to develop a slight wobble within the engine block.

Such a wobbling motion creates a knocking sound as the crankshaft comes into unintended contact with other engine components.

ii. Cracked rod bearings: The connecting rods are responsible for transferring the force from the pistons to the crankshaft.

Each connecting rod has bearings at both ends, allowing it to pivot smoothly on the crankshaft.

If these bearings crack or wear significantly, they lose their ability to hold the connecting rod securely in place.

As a result, the connecting rod moves excessively within its designated space, creating a knocking sound as it contacts the crankshaft or other surrounding components.

What Happens When the Problem Occurs

- Distinctive Noise: The most prominent symptom is a loud, metallic knocking sound, often described as a heavy “clunk-clunk-clunk” or a deeper “thump-thump-thump” noise. Unlike ticking, this sound is usually present throughout the RPM range, becoming more noticeable under acceleration or load.

- Performance Loss: Knocking often accompanies a noticeable loss of engine power and performance. This occurs because the internal friction caused by the worn or damaged components significantly reduces the engine’s efficiency in converting fuel into usable power.

- Other Potential Symptoms: In severe cases, additional symptoms like vibrations, difficulty starting, and even engine misfires might occur, indicating further deterioration of the internal components.

Risks of Ignoring the Problem

Ignoring a knocking sound in your motorcycle engine can have catastrophic consequences:

Catastrophic Engine Failure: The continued operation of an engine with worn or damaged bearings can lead to a complete engine seizure. It occurs when the excessive friction and metal-on-metal contact cause components to bind and lock up, rendering the engine inoperable and requiring a complete rebuild or replacement.

Increased Damage: Every additional mile ridden with a knocking sound exposes the engine to further damage. The initial wear and tear can progress rapidly, potentially impacting other vital components like pistons, connecting rods, and the engine block itself.

Safety Hazard: A complete engine seizure while riding can be a severe safety hazard, causing the motorcycle to lose power abruptly and potentially leading to an accident.

Immediate Action Required

A knocking sound in your motorcycle engine is a critical issue that requires immediate attention from a qualified mechanic.

Ignoring this symptom can lead to expensive repairs, significant safety risks, and potentially even total engine failure.

It’s crucial to prioritize having the problem diagnosed and addressed by a professional as soon as possible.

If the damage isn’t too severe, a rebuild might fix things up. But sometimes those knocks mean a new long block2 is in order.

3. Clattering/slapping Sound

Ever get a slap-slap-slap sound from the top of your engine at idle or low RPM? You’re probably hearing it from the cam chain3.

Cause

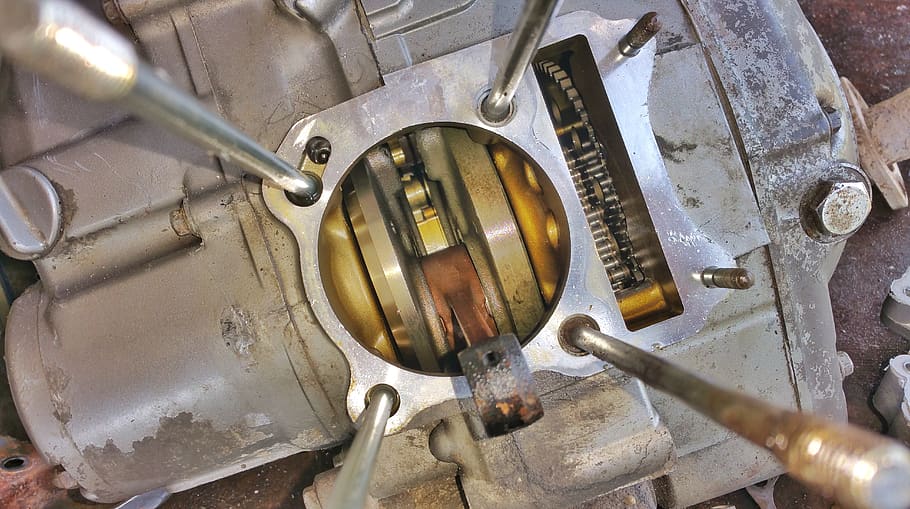

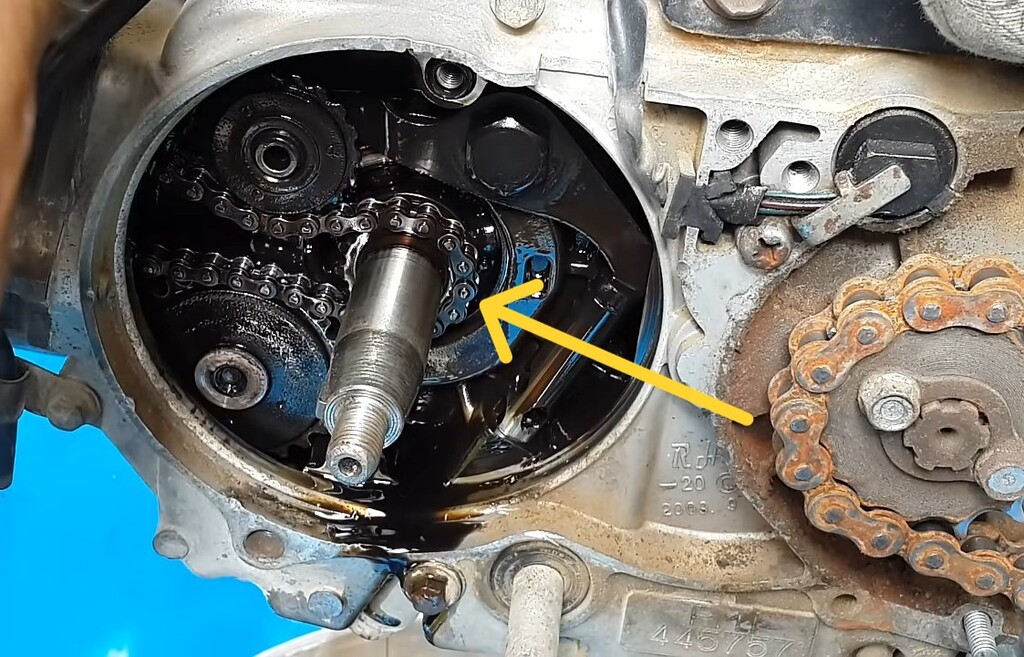

A Worn Cam Chain: It’s the culprit behind the annoying clattering or slapping sound coming from your motorcycle engine.

The cam chain is a vital component that acts as a timing belt4, synchronizing the rotation of the crankshaft with the opening and closing of the engine valves.

It connects the crankshaft sprocket to the camshaft sprocket, ensuring the valves open and close at precise moments in the engine cycle.

Over time, the cam chain experiences wear and tear. The metal links can stretch slightly, and the connecting pins and rollers can wear down, causing the chain to become loose.

This slack allows the chain to slap against the engine case or its guide rails with each rotation.

What Happens When the Problem Occurs

- Distinctive Noise: The most prominent symptom is a distinct clattering or slapping sound coming from the top of the engine, often described as a rapid “slapping-slapping-slapping” or “clacking-clacking-clacking” noise. This sound is usually more noticeable at idle or low RPMs when the engine vibrations are more prominent and other engine noises are less pronounced.

- Performance Issues (Potential): In severe cases, a significantly worn cam chain can cause performance issues like a slight loss of power or hesitation during acceleration. It happens because the misaligned timing due to the loose chain disrupts the optimal valve opening and closing sequence, affecting engine efficiency.

Risks of Ignoring the Problem

Ignoring a worn cam chain can lead to more significant problems and potentially damage your engine:

Increased Chain Wear and Damage: The continued slapping of the loose chain against the engine case can accelerate its wear and tear. This can lead to further stretching, breakage of the chain links, or even damage to the engine case itself.

Valve Timing Issues: As the chain continues to stretch, it can throw off the valve timing significantly. It disrupts the optimal intake and exhaust cycles, leading to reduced engine performance, increased fuel consumption, and potentially engine damage.

Engine Damage: In the worst-case scenario, a severely worn cam chain can jump teeth on the sprockets, causing the valves to open or close at completely incorrect times. The possible aftereffect is severe engine damage, including bent or broken valves, piston-to-valve contact, and potentially even engine failure.

Prevention and Maintenance

Regularly checking the cam chain tension and replacing it when it shows signs of wear is crucial for maintaining smooth engine operation and preventing costly repairs down the road.

The manufacturer’s recommended service schedule typically specifies intervals for cam chain inspection and replacement.

Also, being attentive to the distinctive clattering sound can be a good indicator of potential cam chain issues.

4. Detonation (Pinging)

Causes

i. Low Octane Fuel: Using fuel with a lower octane rating5 than your motorcycle manufacturer recommends can lead to detonation6.

Octane rating signifies a fuel’s ability to resist self-ignition under pressure and heat.

Low-octane fuel ignites more readily under these conditions, potentially igniting prematurely before the spark plug fires.

ii. Excessive Heat: This can be caused by:

- Lean fuel mixtures: An air-fuel mixture with too much air and not enough fuel burns hotter, increasing the risk of detonation. This might occur due to:

- Malfunctioning fuel injection system: If the system is faulty, it might deliver an incorrect amount of fuel.

- Air leaks: Unmetered air entering the engine through leaks can create a lean mixture.

- Engine modifications: Modifications like performance air filters or aftermarket exhaust systems can alter the air-fuel ratio, potentially leading to a leaner mixture and increased heat.

iii. Incorrect Ignition Timing: If the spark plug fires too early in the compression stroke, it can ignite the air-fuel mixture prematurely before it’s fully compressed, causing detonation. This might be due to:

- Faulty ignition components: Worn spark plugs, malfunctioning ignition coils, or timing chain issues can all contribute to incorrect timing.

- Improper installation: If any timing components are not installed correctly during maintenance or repairs, it can affect the timing.

What Happens When the Problem Occurs

Distinctive Noise: The most prominent symptom is a high-pitched metallic pinging sound, often described as a rapid “tink-tink-tink” or “ping-ping-ping” noise.

This sound is usually noticeable under acceleration, especially when pushing the engine hard, as the pressure and heat inside the cylinder are higher.

Performance Loss (Potential): In severe cases, detonation can cause a slight loss of power or hesitation during acceleration.

It happens because the pre-ignition7 disrupts the normal combustion process, reducing engine efficiency and power output.

Risks of Ignoring the Problem

Ignoring detonation can lead to several potentially serious consequences:

Piston Damage: The high pressure and temperature during detonation can cause significant damage to the pistons. This can manifest as:

- Holes or cracks: The intense pressure can cause the piston crown to crack or even break entirely.

- Scuffing or scoring: The excessive heat can lead to scuffing or scoring on the piston surface, impacting its ability to seal properly.

Spark Plug Damage: The intense heat generated during detonation can damage the spark plugs, leading to:

- Premature Engine Wear: Detonation can accelerate wear and tear on various engine components due to the excessive heat and pressure, potentially leading to:

- Valve damage: The high temperatures can damage the valves and their seats, affecting engine performance and potentially leading to oil leaks.

Cylinder head damage: Over time, detonation can contribute to warping or cracking of the cylinder head.

- Electrode erosion: The high temperatures can accelerate the wear and tear of the spark plug electrodes, reducing their effectiveness.

- Melted electrodes: In extreme cases, the spark plug electrodes might even melt due to the extreme heat.

Possible Fixes

- Use the recommended octane fuel: Always refer to your motorcycle’s owner’s manual for the recommended fuel octane rating and use fuel that meets or exceeds that specification.

- Address lean fuel mixtures: Consult a qualified mechanic to diagnose and address any issues with the fuel injection system or air leaks that might be causing a lean mixture.

- Revert engine modifications: If engine modifications are suspected to be contributing to detonation, consider reverting them to the stock configuration to restore the original air-fuel ratio and ignition timing.

- Inspect and replace faulty ignition components: Regularly inspect and replace worn spark plugs, check for faulty ignition coils, and have the timing chain inspected and adjusted if necessary.

Maintenance Advice

- Regular maintenance: Following the recommended maintenance schedule in your owner’s manual is crucial. This includes regular spark plug replacements, air filter cleaning, and fuel system cleaning, which can help prevent detonation by ensuring proper engine operation and air-fuel mixture.

- Listen to your engine: Be attentive to any unusual engine noises, such as pinging, and address them promptly. Early detection and addressing of detonation can help prevent significant engine damage and costly repairs.

- Consult a qualified mechanic: If you suspect detonation or experience any unusual noises, consult a qualified mechanic for proper diagnosis and repair to ensure the safety and longevity of your motorcycle.

FAQs About Motorcycle Engine Noise When Accelerating

What’s the issue when a bike makes a light knocking sound at idle that goes away when accelerating?

A single tapping knock at idle often indicates a loose or worn valve tappet8. Have the valve clearances inspected – an adjustment may fix it. Monitor to ensure it doesn’t worsen.

I notice a rattle that seems to come from the top end around 4000 RPM. Anything to worry about?

A rattle isolated to higher RPMs could be related to the cam chain or tensioner. Inspect for excess slack or worn parts. No immediate danger but don’t ignore – it may need attention soon.

My bike has 50,000 miles and is starting to make some weird clunking noises. Is it time for an engine rebuild?

Not necessarily. Have a mechanic thoroughly inspect for the source – it could be something simpler like worn suspension bushes. Only rebuild if actual engine damage is found. Replacing high mileage parts is often a more cost effective first step.

I put 89 octane in my bike that requires 91. Will one time cause damage?

Likely no permanent harm from one tank of lower octane. But use the recommended grade or higher from now on to prevent long-term problems from detonation like preignition or ringing noises.

My engine makes popping sounds under heavy acceleration. How much of an issue is this?

Pops could indicate an ignition issue allowing unburnt fuel into the exhaust. Have the plugs, wires and ignition timing checked – it’s better not to ignore potential problems. Catching small issues early prevents costly repairs down the road.

My engine makes a whining noise that seems to come from the transmission. What could it be?

Whining noises from the transmission can indicate worn gears or bearings. It’s crucial to have a mechanic diagnose the source of the noise as soon as possible to prevent further damage.

I hear a grinding noise when I shift gears. Is this normal?

Grinding noises are not typical and could indicate worn clutch plates, shifter forks, or other internal transmission components. Consult a mechanic for a proper diagnosis and repair.

My bike backfires when I decelerate. What’s causing this?

Backfiring can occur due to a lean fuel mixture, faulty spark plugs, or problems with the ignition system. It’s essential to address this issue to prevent engine damage and potential safety hazards.

Is it safe to ride my motorcycle if it’s making a strange noise?

It’s generally not recommended to ride your motorcycle if it’s making a new or unusual noise. Ignoring the issue could lead to further damage and potential safety risks. Play it safe and have the noise checked by a qualified mechanic before riding again.

How often should I have my motorcycle serviced to prevent engine noises?

Regular maintenance is crucial to prevent engine noises and other problems. Follow the manufacturer’s recommended service schedule, which typically includes oil changes, filter replacements, and valve adjustments at specific intervals.

- The small spaces inside the engine cylinder where the air-fuel mixture is ignited and burned. ↩︎

- The complete engine block assembled with pistons, cylinders, crankshaft, and camshaft, excluding the head and external components. ↩︎

- A chain that drives the camshaft, which controls the opening and closing of the engine valves. ↩︎

- A belt that synchronizes the timing of the valves and pistons in the engine. ↩︎

- A number indicating a fuel’s resistance to knocking or pinging under pressure. Higher octane fuels are less likely to detonate prematurely. ↩︎

- When the air-fuel mixture ignites prematurely and burns too rapidly, causing a knocking sound and potentially damaging the engine. ↩︎

- When the air-fuel mixture ignites in the cylinder too early, before the spark plug fires. ↩︎

- A small component that transmits the camshaft’s motion to open and close the engine valves. ↩︎