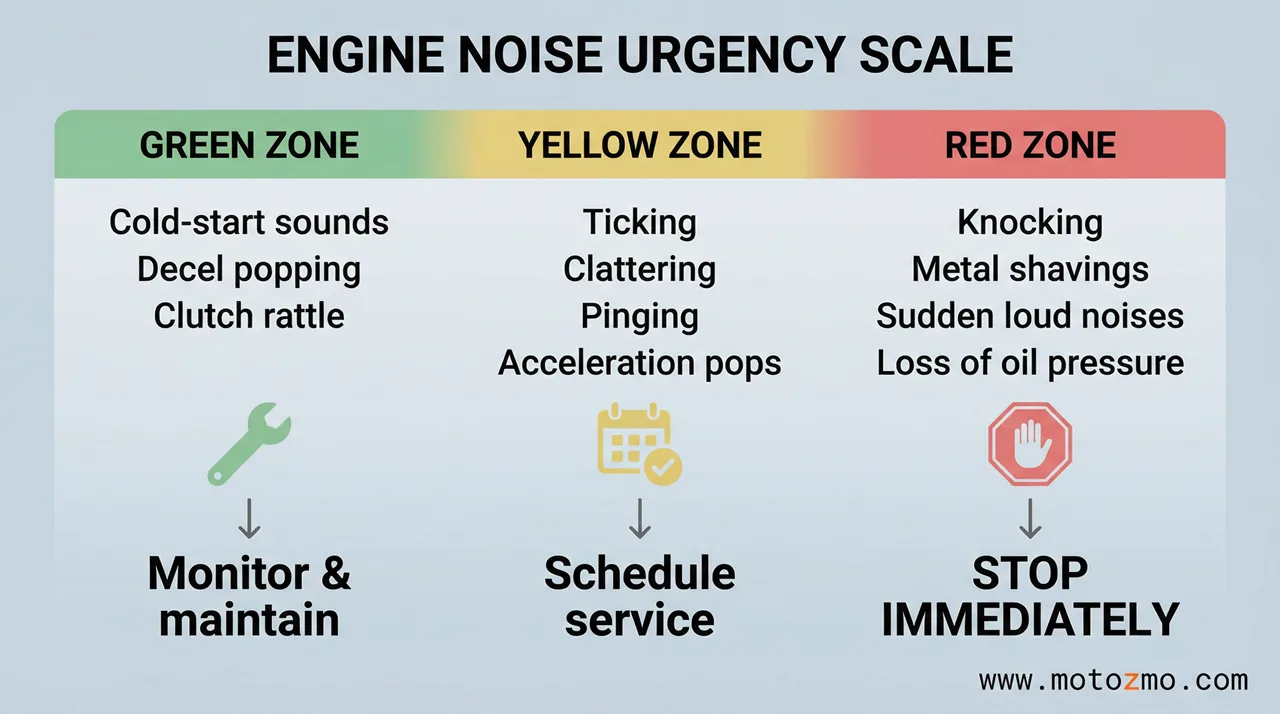

Most acceleration noises trace back to five culprits: loose valves (ticking), worn bearings (knocking), stretched cam chain (clattering), fuel detonation (pinging), or exhaust leaks (popping). Some sounds signal normal operation. Others warn of imminent engine failure.

The difference matters. A rhythmic tick from slightly loose valves gives you weeks to schedule an adjustment. A deep metallic knock from failing rod bearings gives you minutes before catastrophic seizure.

This guide walks you through each noise type, explains what creates it mechanically, and tells you exactly what to do next. If you’re diagnosing motorcycle issues for the first time, start with the quick diagnosis table below. Match your sound to the likely cause, then read the detailed section for confirmation and fixes.

🎯 Key Takeaways

- Seat covers protect seats, add comfort, and extend lifespan. Covers are far cheaper than replacing the whole seat.

- Materials like leather, mesh, neoprene, and rubber each serve different needs.

- A good cover boosts style and safety, especially in wet conditions.

- Covers are far cheaper than replacing the whole seat.

- Quick Diagnosis: Match Your Noise to the Cause

- What Creates Each Noise Inside Your Engine

- When Engine Noise Signals Normal Operation

- Heat and Engine Noise Connection

- Diagnostic Steps: Isolate the Noise Source

- Prevention: Keep Engine Noise From Developing

- When to Stop Riding Immediately

- FAQs About Motorcycle Engine Noise When Accelerating

Quick Diagnosis: Match Your Noise to the Cause

| Noise Type | Sound Description | When It Occurs | Most Likely Cause | Urgency Level |

|---|---|---|---|---|

| Ticking | Rhythmic “tick-tick-tick” | Idle and low RPM | Loose valves, worn valve seals | Moderate – Schedule service |

| Knocking | Heavy “clunk-clunk-clunk” | All RPM, worse under load | Worn crankshaft or rod bearings | Critical – Stop riding |

| Clattering/Slapping | Rapid “slap-slap-slap” | Idle and low RPM | Stretched cam chain | Moderate to High |

| Pinging | Metallic “tink-tink-tink” | Hard acceleration | Detonation from low octane fuel | Moderate – Address soon |

| Popping/Backfiring | Sharp pops | Deceleration or acceleration | Lean mixture, exhaust leak, ignition fault | Moderate |

| Whining | High-pitched whine | Acceleration or all RPM | Transmission gears, wheel bearings | Varies by source |

What Creates Each Noise Inside Your Engine

Understanding the mechanical cause helps you communicate with mechanics and avoid overpaying for unnecessary repairs. Each noise originates from a specific component behaving outside its design parameters.

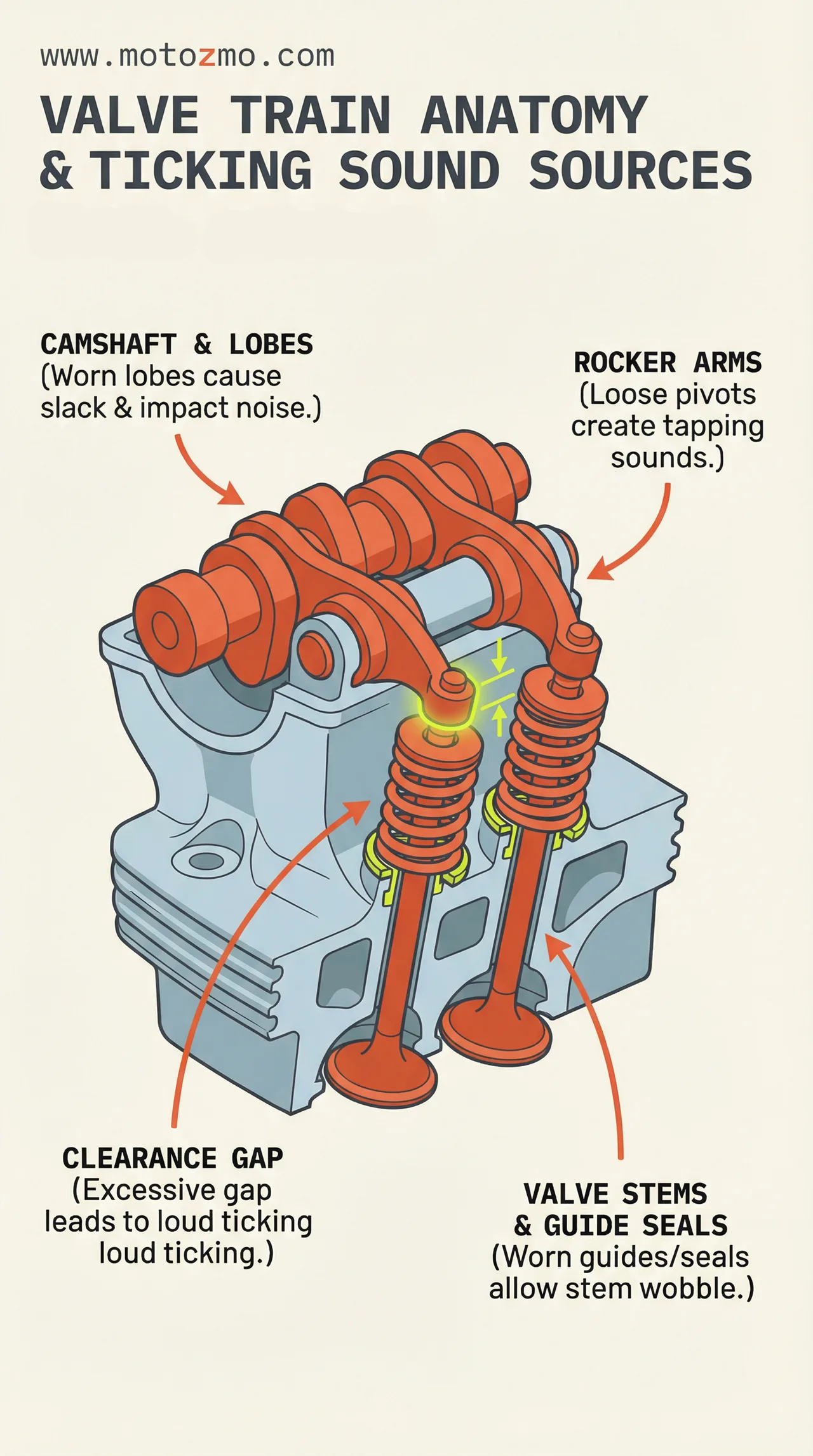

01. Ticking Sound: Valve Train Issues

That rhythmic tick-tick-tick usually radiates from the cylinder head. The valve train sits there, opening and closing intake and exhaust valves thousands of times per minute.

What Causes It

Excessive valve clearance tops the list. Manufacturers specify a gap between the camshaft lobe and the valve stem (or rocker arm). This clearance allows for thermal expansion when the engine heats up.

Over time, components wear. The gap widens. Now the camshaft lobe strikes the valve mechanism with each rotation instead of smoothly pressing against it. That impact creates the tick.

Three specific causes:

- Loose valve adjustment – The clearance drifted beyond specification through normal wear

- Worn valve guide seals – Oil seeps past degraded seals, causing valves to stick momentarily

- Fatigued valve train components – Rocker arms, tappets, or shims develop wear patterns

Why It Gets Louder When Accelerating

Higher RPM means more valve events per second. More impacts equal louder noise. The ticking also becomes harder to isolate because other engine sounds compete with it.

What Happens If You Ignore It

The constant metal-on-metal contact accelerates wear on both the camshaft lobes and valve components. Clearances grow larger. Eventually, valve timing suffers.

Worst case: A valve stays partially open during combustion. Hot exhaust gases burn the valve face and seat. Now you’re looking at a cylinder head rebuild instead of a simple adjustment.

The Fix

Most motorcycles require valve adjustments every 12,000–16,000 miles. Some shim-under-bucket designs demand more labor time. Budget $150–$400 depending on your bike’s configuration.

If you ride a carbureted bike, valve issues can compound with fuel delivery system differences that mask symptoms or create additional problems.

02. Knocking Sound: Bottom-End Bearing Failure

A deep, diesel-like knock pulsing from the lower engine spells serious trouble. This sound rarely offers second chances.

What Causes It

The crankshaft spins on plain bearings, thin shells of softer metal that sacrifice themselves to protect the crankshaft journals. Connecting rods attach to the crankshaft via similar bearings.

When these bearings wear through their protective layer, metal contacts metal. The crankshaft develops play within the engine case. Connecting rods wobble on worn journals.

Two primary failure points:

- Main bearings – Support the crankshaft at both ends

- Rod bearings – Connect the pistons to the crankshaft

Why It Sounds Different From Ticking

Ticking originates from lightweight valve train components making high-frequency contact. Knocking comes from heavy rotating assembly parts — crankshaft, connecting rods, pistons — moving with excessive clearance.

The mass involved creates a deeper, more resonant sound. It often worsens under load because combustion pressure pushes the piston harder against the worn bearing surface.

What Happens If You Keep Riding

The bearing material continues disintegrating. Metal particles contaminate the oil. Other bearings throughout the engine starve for lubrication.

Final outcome: The connecting rod breaks free or welds itself to the crankshaft. Either scenario destroys the engine internally and potentially cracks the cases externally.

According to RevZilla’s maintenance guides, rod bearing failure ranks among the most expensive mechanical failures on any motorcycle.

The Fix

Stop riding immediately. Have the bike trailered to a qualified mechanic. Diagnosis involves dropping the oil pan (if accessible) to inspect bearings, or performing an engine teardown.

Repair options range from bearing replacement ($800–$2,000) to complete engine rebuild ($2,500–$5,000+) depending on collateral damage. Sometimes a replacement long block offers better value than rebuilding.

If your engine experienced high-RPM engine strain before the knock appeared, heat stress likely accelerated the bearing wear.

03. Clattering or Slapping Sound: Cam Chain Problems

A slapping noise from the top-front of your engine often points to the cam chain, the timing chain connecting your crankshaft to camshaft(s).

What Causes It

The cam chain stretches over time. Not from physical elongation of the metal links, but from wear on the pins and rollers that connect each link. This accumulated slop adds up to measurable chain slack.

Most motorcycles use automatic cam chain tensioners. Spring pressure or hydraulic force pushes a guide against the chain’s slack side. But tensioners have limits. Once the chain stretches beyond the tensioner’s adjustment range, slack remains.

That loose chain slaps against its guides and engine case with each crankshaft rotation.

When It’s Loudest

Idle and low RPM produce the most noticeable slapping. At higher RPM, centrifugal force helps keep the chain taught. Oil pressure also peaks, improving hydraulic tensioner performance.

What Happens If You Ignore It

A slack cam chain can jump teeth on the sprockets. This throws valve timing off. Mild timing shift causes performance loss. Severe shift causes piston-to-valve contact.

Interference engines (most modern motorcycles) leave no clearance margin. If a valve opens when a piston occupies that space, both components destroy each other.

The Fix

Cam chain replacement runs $300–$800 at most shops. The job often requires significant disassembly to access the chain and tensioner. Some bikes allow top-end access without splitting the cases. Others demand complete engine removal.

Different motorcycle engine types present varying difficulty levels for this repair. V-twins and inline-fours often require more labor than singles.

04. Pinging or Detonation: Abnormal Combustion

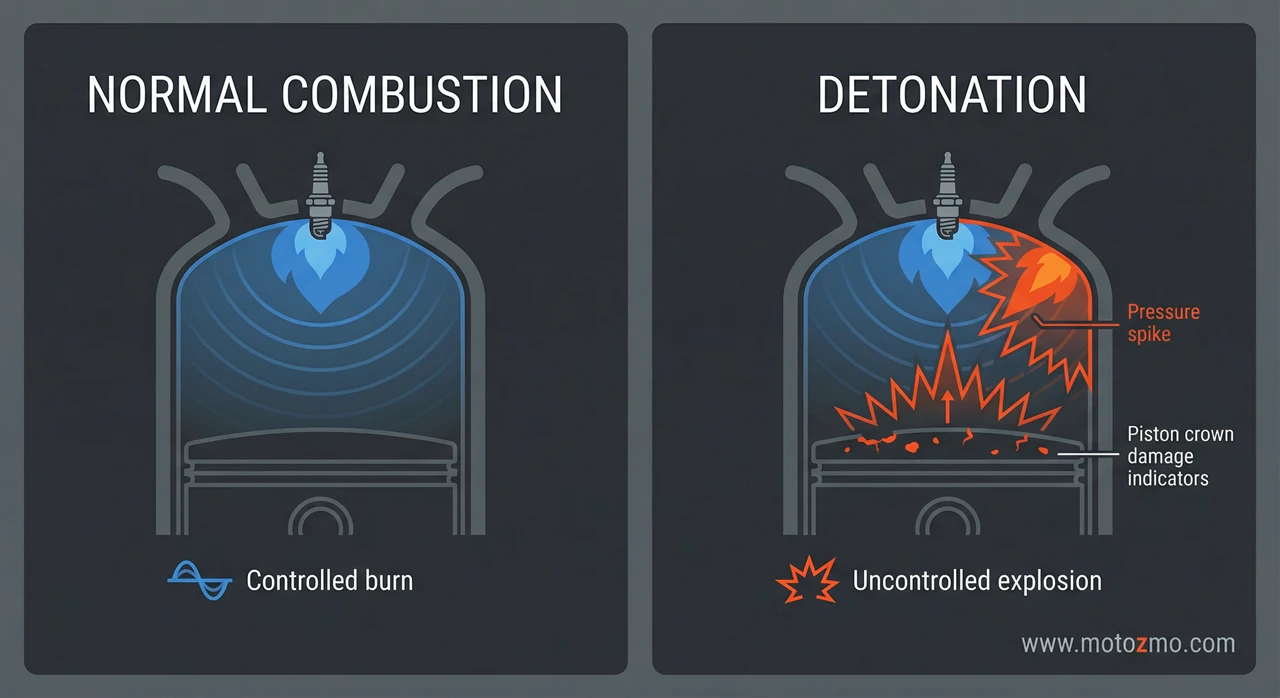

That metallic tink-tink-tink under hard acceleration indicates detonation, which is uncontrolled combustion happening before the spark plug fires.

What Causes It

Normal combustion: The spark plug ignites the air-fuel mixture. A flame front travels smoothly across the combustion chamber.

Detonation: Pressure and heat cause the remaining unburned mixture to spontaneously ignite before the flame front reaches it. Two flame fronts collide. The resulting pressure spike hammers the piston crown.

Three primary triggers:

i. Low octane fuel: Octane rating measures a fuel’s resistance to premature ignition. Your motorcycle’s compression ratio dictates minimum octane requirements. Using 87 octane in an engine designed for 91+ invites detonation.

ii. Lean air-fuel mixture: Too much air, not enough fuel. The mixture burns hotter. Combustion chamber temperatures rise. Detonation threshold drops.

Causes include:

- Clogged fuel injectors

- Failing fuel pump

- Intake air leaks

- Incorrect fuel mixture adjustment

iii. Excessive ignition advance: Spark timing set too early gives the flame front too much head start. Cylinder pressure peaks before the piston reaches optimal position.

What Damage Occurs

Detonation erodes piston crowns. It melts spark plug electrodes. It cracks ring lands. The repeated pressure spikes fatigue connecting rod bearings.

Sustained detonation destroys engines. Even brief detonation episodes leave permanent damage markers visible during teardown.

The Fix

- Switch to the manufacturer’s recommended octane immediately

- Inspect for intake leaks (spray carb cleaner around intake boots while idling; RPM change indicates a leak)

- Check ignition timing if adjustable

- Clean or replace fuel injectors

- Verify fuel pump pressure meets specification

If modifications altered your engine’s state of tune, the original fuel mapping may no longer match. Adjusting the air-fuel mixture often resolves detonation on modified bikes.

05. Popping and Backfiring: Exhaust-Side Issues

Pops on deceleration often fall within normal parameters. Pops during acceleration suggest problems.

What Causes Deceleration Pops

When you close the throttle, fuel delivery drops sharply. Some unburned fuel enters the hot exhaust system. It ignites there instead of the combustion chamber.

Bikes with aftermarket exhausts pop more. Stock exhausts include air injection systems and catalytic converters that consume this unburned fuel.

What Causes Acceleration Pops

Ignition misfires leave unburned fuel in the cylinder. That fuel enters the exhaust pipe. Hot exhaust components ignite it.

Causes include:

- Fouled or worn spark plugs

- Failing ignition coils

- Cracked plug wires or boots

- Lean fuel mixture

If your engine dies when applying throttle, the underlying cause often creates popping symptoms first.

The Fix

Deceleration pops on a stock bike warrant fuel system inspection. On modified bikes with aftermarket exhaust, some popping is expected.

Acceleration pops demand spark plug inspection, coil testing, and fuel system diagnosis. Address promptly. Repeated misfires wash cylinder walls with raw fuel, accelerating ring and bore wear.

When Engine Noise Signals Normal Operation

Not every sound indicates failure. Engines produce operational noises that concern new riders unnecessarily.

Normal Sounds

| Sound | When It Occurs | Why It Happens |

|---|---|---|

| Whirring | All RPM | Gear mesh in transmission and primary drive |

| Light tapping | Cold start | Valve clearance tightens as engine warms |

| Fuel pump whine | Key on, engine off | Electric pump pressurizing fuel rail |

| Clutch rattle | Idle in neutral | Clutch basket play against hub |

| Exhaust tick | After shutdown | Metal cooling and contracting |

The engine braking noise you hear during deceleration falls into normal operation. That mechanical resistance comes from compression fighting piston movement.

Heat and Engine Noise Connection

Thermal expansion affects every engine component. Understanding this relationship helps distinguish normal warm-up sounds from developing problems.

Cold Engine vs. Hot Engine

Cold engines run with tighter clearances in some areas, looser in others. Pistons haven’t expanded fully. Neither have cylinder bores. This mismatch can create temporary piston slap, a hollow knocking sound that disappears once operating temperature stabilizes.

Valve clearances work opposite. Cold clearances sit wider than hot clearances (on most designs). That’s why valve noise often peaks during warm-up, then quiets.

If a noise appears only when hot, suspect heat-related expansion causing contact between components. Track how hot a motorcycle engine gets and whether noise correlates with temperature spikes.

Diagnostic Steps: Isolate the Noise Source

Before visiting a mechanic, gather information that speeds diagnosis.

Step 1: Identify When the Noise Occurs

- Cold only, hot only, or both?

- Idle, acceleration, deceleration, or steady cruise?

- Specific RPM range?

- Under load (climbing hills) or unloaded (neutral)?

Step 2: Locate the Sound

- Top end (cylinder head area) = likely valve train or cam chain

- Bottom end (crankcase area) = likely bearings or transmission

- Front of engine = cam chain, water pump

- Rear of engine = clutch, transmission output

Step 3: Note Recent Changes

- New fuel type or brand?

- Recent oil change (or overdue)?

- Any maintenance performed?

- Modifications installed?

Step 4: Check the Basics

- Oil level and condition

- Coolant level (if liquid-cooled)

- Loose heat shields or exhaust components

- Damaged spark plug wires

Sometimes the noise originates outside the engine entirely. Loose heat shields vibrate against exhaust pipes. Failing wheel bearings create whines that sound internal. Chain slapping the swingarm mimics engine noise.

If your motorcycle engine keeps cutting out alongside the noise, electrical or fuel delivery issues likely contribute.

Prevention: Keep Engine Noise From Developing

Proper maintenance prevents most noise-causing failures.

Oil: Your First Defense

Engine oil cushions bearing surfaces, lubricates valve train components, and dampens mechanical noise. Neglected oil loses viscosity and contaminates with combustion byproducts.

- Change oil at manufacturer intervals (typically 3,000–6,000 miles)

- Use the specified viscosity grade

- Replace the filter every change

- Check level weekly on high-mileage bikes

Quality motorcycle engine cleaners help remove deposits during oil changes, particularly on engines with significant miles.

Valve Adjustments: Don’t Skip Them

Valve service intervals exist for a reason. Clearances drift predictably based on operating hours. Adjustment restores specification.

Skipped valve services lead to:

- Increased valve train noise

- Reduced performance

- Potential valve damage

Fuel Quality: Use What’s Specified

Your owner’s manual states minimum octane requirements. Meet or exceed them. Lower octane fuels save pennies per gallon but risk thousands in detonation damage.

Avoid ethanol blends above 10% unless your bike is specifically certified for them. Ethanol attracts water and degrades rubber fuel system components.

Listen Actively

Engines telegraph problems before failure. That new sound you noticed last week? It’s louder now. Address unusual noises promptly rather than hoping they resolve.

Regular riders develop baseline knowledge of their bike’s normal sounds. Trust your instincts when something changes.

When to Stop Riding Immediately

Certain symptoms demand immediate shutdown:

- Sudden loud knocking – Rod or main bearing failure imminent

- Metal shavings in oil – Internal component disintegrating

- Loss of oil pressure (warning light or gauge) – Bearing damage occurring

- Seized feeling – Engine trying to lock up

- Smoke from engine cases – Oil leak onto hot surfaces, or worse

Continuing to ride through these symptoms converts repairable damage into total loss. The cost of a tow pales against the cost of a new engine.

If you’re pushing engine noise near redline and something sounds wrong, back off immediately. High-RPM failures progress faster.

FAQs About Motorcycle Engine Noise When Accelerating

Why does my motorcycle tick at idle but stop when I accelerate?

Valve train clearances cause this. At idle, loose valves produce audible ticking. Higher RPM increases oil pressure and masks the sound. Schedule a valve adjustment soon.

Is it normal for a motorcycle to make noise when cold?

Yes. Cold engines produce piston slap and louder valve noise until components reach operating temperature. These sounds should disappear within 2-5 minutes of riding.

Can low oil cause engine noise during acceleration?

Absolutely. Insufficient oil starves bearings and valve train components. Metal-on-metal contact creates knocking and ticking. Check oil level immediately if noise appears suddenly.

Why does my bike ping only on hills or during hard acceleration?

Load increases cylinder pressure and temperature. These conditions trigger detonation in engines running low-octane fuel or lean mixtures. Use premium fuel and check for intake leaks.

Should I worry about exhaust popping on deceleration?

Usually not. Deceleration popping is normal on many bikes, especially with aftermarket exhausts. Popping during acceleration indicates ignition or fuel delivery problems requiring diagnosis.

How much does it cost to fix a knocking motorcycle engine?

Costs range from $800 for bearing replacement to $5,000+ for complete rebuild. Severity depends on how long the engine ran after knock appeared. Early diagnosis saves money.

Can a loose chain cause engine-like noise?

Yes. A slack drive chain slapping the swingarm or chain guard mimics engine noise. Check chain tension and adjustment before assuming internal engine problems.

What does a failing transmission sound like?

Whining under acceleration suggests worn gears or bearings. Grinding during shifts indicates worn clutch plates, bent shift forks, or damaged gear dogs. Both require professional diagnosis.

How often should I service my motorcycle to prevent engine noise?

Follow manufacturer intervals, typically oil changes every 3,000-6,000 miles, valve adjustments every 12,000-16,000 miles. Consistent maintenance prevents most noise-causing failures.

Is it safe to ride if my motorcycle makes a strange noise?

Stop and assess. Light ticking may allow careful riding to a shop. Loud knocking demands immediate shutdown and towing. When uncertain, err toward caution, engine damage escalates quickly.