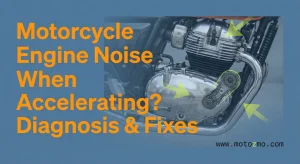

Hot-start failures happen when heat disrupts one of four critical systems — electrical (most common), fuel delivery, compression, or air intake.

The usual suspects are a weak battery struggling against higher compression, failing ignition coils building excessive resistance, or vapor lock preventing fuel flow. On carbureted bikes, heat-soaked float bowls cause flooding.

Let’s break down exactly what fails when motorcycle won’t start when engine is hot and how to fix it before your next ride.

🎯 Key Takeaways

- The “Core Four”: Heat disrupts Spark, Fuel, Air, and Compression.

- Battery Paradox: Hot engines require more cranking power, but heat reduces battery efficiency.

- Vapor Lock: Modern fuel boils at low temps (100°F+), creating air pockets that stop fuel flow.

- Ignition Resistance: Coils and CDI boxes often fail only when they reach operating temperature.

- Quick Fix: Park in the shade, open the gas cap to vent pressure, and wait 20 minutes.

- Why Heat Breaks the Starting Process

- Test This First: Battery Under Heat Stress

- Ignition System Failures (Primary Culprit)

- Fuel System Problems

- Compression Issues from Heat Expansion

- Starter Motor Heat Soak

- Temperature Sensors Lying to ECU

- Don’t Overlook the Kill Switch

- Diagnostic Flowchart for Hot-Start Failure

- Prevention: Stop Hot-Start Problems Before They Start

- When to Call a Mechanic

- FAQs About Motorcycle Won’t Start When Engine Is Hot

Take the TEST for troubleshooting your motorcycle that won’t start when hot.

Engine Vital Check

Hot-Start Diagnostic Assistant

Is your battery voltage above 12.4V after your ride?

Why Heat Breaks the Starting Process

Your engine needs four elements to start: spark, fuel, air, and compression. Heat attacks all four.

Spark systems fail first. Electrical resistance climbs as components heat up. A coil that fires perfectly at 70°F can fail completely at 200°F.

Fuel vaporizes before reaching cylinders. Modern gasoline boils at temperatures as low as 100°F under certain conditions, your engine compartment easily hits 250°F after a ride.

Compression increases from metal expansion. Hot pistons and cylinders expand, creating tighter tolerances. A weak battery that cranks a cold engine perfectly won’t have enough power to turn over a hot one.

Air density drops. Hot air carries less oxygen. Less oxygen means weaker combustion, making starts harder even when everything else works.

For related engine performance issues, see our guide on common motorcycle problems and fixes.

Test This First: Battery Under Heat Stress

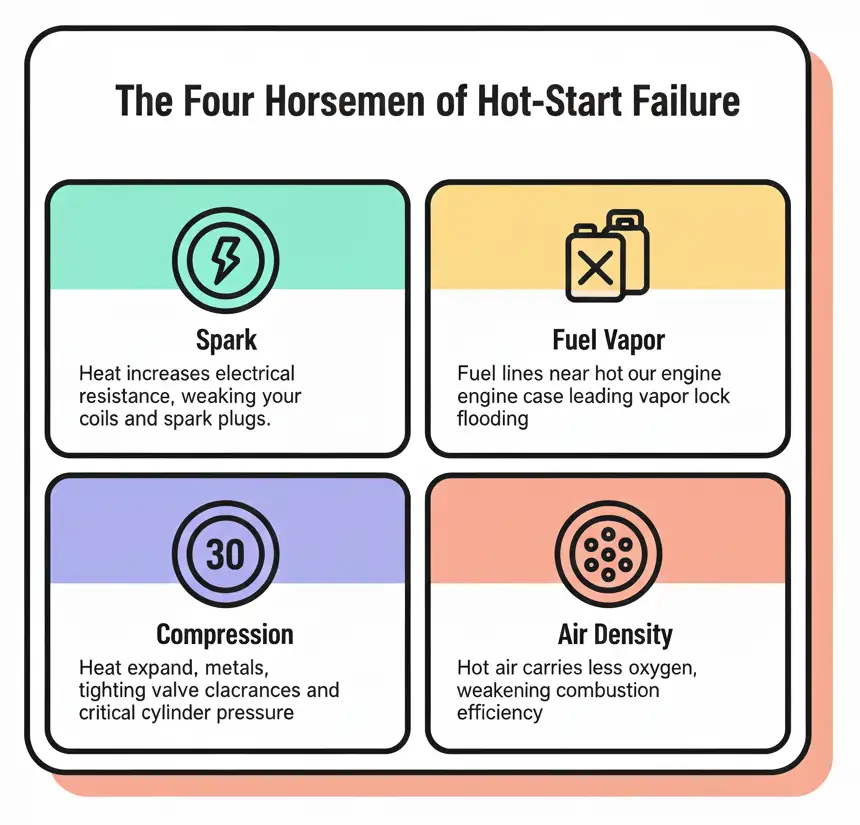

Before touching anything else, test your battery. Heat creates a cruel paradox: hot engines need MORE cranking power precisely when batteries deliver LESS.

The voltage test:

- Cool engine: Battery should read 12.6V or higher

- After a 30-minute ride: Check again (should hold 12.4V minimum)

- While cranking hot: Voltage shouldn’t drop below 10V

What you’ll see with a failing battery:

- Slow cranking when hot (versus quick cranking when cold)

- Clicking sounds instead of engine turnover

- Lights dimming significantly during start attempts

- Voltage dropping to 9V or below during cranking

A battery that tests at 12.3V seems adequate but will struggle with hot starts. Replace anything below 12.4V.

The terminal check matters too. Heat accelerates corrosion. Clean terminals with a wire brush and baking soda solution. Tight connections are critical. A loose ground wire mimics a dead battery.

For more on heat-related engine behavior, read about how hot motorcycle engines actually get.

Ignition System Failures (Primary Culprit)

Heat transforms reliable ignition components into failure points. Three parts betray you when temperatures spike.

Ignition Coils Building Resistance

Coils generate spark by converting low battery voltage into thousands of volts. Internal resistance kills this process when heat soaks the windings.

Test for failing coils:

- After riding, carefully touch each coil (use the back of your hand)

- If one coil feels significantly hotter than others, it’s failing

- Use a multimeter: primary resistance should match your service manual specs (typically 0.5-3 ohms)

- Secondary resistance varies by model but usually falls between 10K-25K ohms

The fix: Replace coils in pairs if your bike has multiple cylinders. Mixing old and new coils creates uneven spark timing.

Spark Plugs Losing Gap

Heat expands plug electrodes, widening the gap. A gap of 0.028 inches when cold becomes 0.032 inches when hot—enough to prevent reliable spark generation.

Visual diagnosis:

- Black, sooty deposits indicate rich mixture (common before hot-start failure)

- White, chalky appearance shows lean running or overheating

- Oil-fouled plugs (wet, black) point to compression issues

Check gap with feeler gauges. Replace plugs showing any damage or deposits. Use the heat range specified in your manual, running too cold causes fouling, too hot causes pre-ignition.

CDI Box Heat Failure

The Capacitor Discharge Ignition box orchestrates spark timing. Age and heat cause internal component failure.

Signs of CDI failure:

- Intermittent misfires increasing as engine warms

- Complete loss of spark when hot

- Bike runs perfectly cold, then dies without warning when hot

Testing CDI boxes requires specialized equipment. The practical test: swap with a known-good unit. Many riders carry a spare CDI in their tool roll because replacement is the only real fix.

If your engine keeps cutting out intermittently, the CDI might be the root cause.

Fuel System Problems

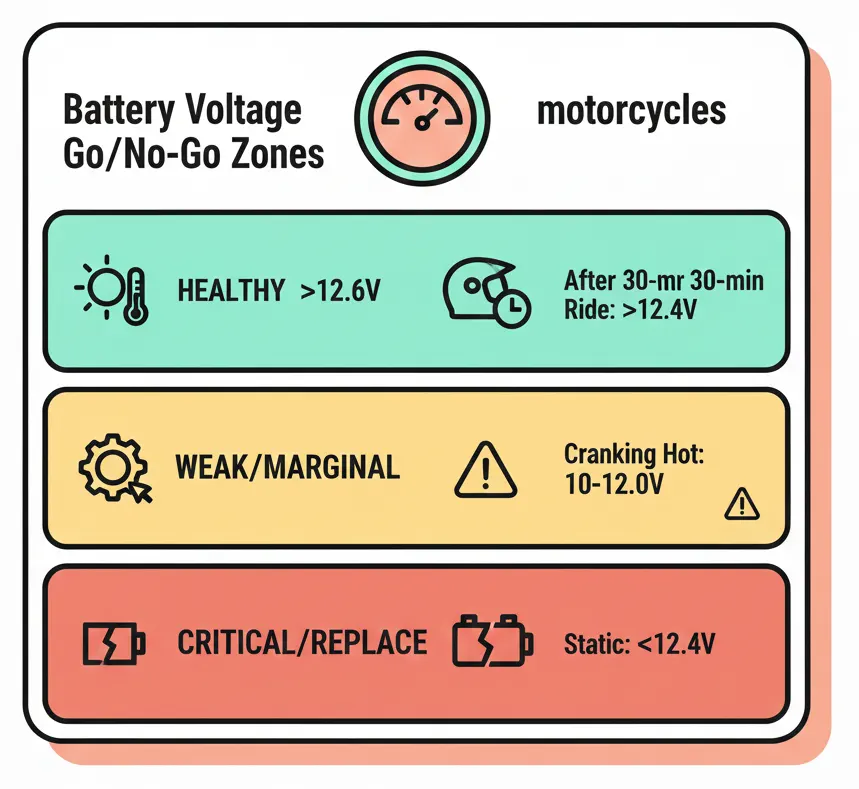

Carbureted and fuel-injected bikes suffer different heat-related fuel failures.

Vapor Lock: The Invisible Blockage

Modern gasoline vaporizes at surprisingly low temperatures. When liquid fuel turns to vapor in your fuel lines, pumps can’t move it. You’re trying to compress air instead of liquid.

Vapor lock happens when:

- Fuel lines run too close to exhaust components

- Ambient temperature exceeds 95°F

- You’re riding at high altitude (fuel boils at lower temps)

- Tank is less than 1/4 full (more vapor space, fuel heats faster)

On carbureted bikes: Float bowls sitting above hot cylinders become heat sinks. After shutdown, fuel boils in the bowls, flooding the engine or creating vapor pockets.

On fuel-injected bikes: Vapor lock typically hits the fuel pump. Electric pumps generate heat themselves. Combined with engine heat, fuel inside the pump housing vaporizes.

The quick fix:

- Park in shade and open the fuel cap (releases pressure)

- Pour cold water over fuel lines and pump (not electrical connections)

- Wait 15-20 minutes for condensation

- Try starting with throttle completely closed (carb) or slightly open (EFI)

Long-term solutions:

- Reroute fuel lines away from exhaust pipes

- Add heat shielding to fuel lines

- Keep tank above half-full in hot weather

- Consider an aftermarket in-line electric pump on carbureted bikes

Understanding the differences in carburetor versus fuel injection systems helps diagnose which type of vapor lock you’re facing.

Flooded Carburetors

Heat causes fuel to expand. Float needle valves stick. Suddenly you’re pouring liquid gasoline into cylinders faster than they can burn it.

Symptoms:

- Strong fuel smell after failed start attempts

- Black smoke from exhaust

- Wet spark plugs when removed

The clearing procedure:

- Remove spark plugs and let cylinders air out (10 minutes)

- Dry plugs with compressed air or replace them

- Hold throttle wide open while cranking (increases airflow)

- Don’t touch throttle during first start attempt after clearing

If flooding repeats, check float heights and needle valve condition. Worn needles need replacement, not adjustment.

Fuel Delivery Testing

Your fuel system should deliver consistent flow, hot or cold.

Simple flow test:

- Disconnect fuel line at carburetor or fuel rail

- Point line into container

- Turn on ignition (EFI) or use petcock (carb)

- Fuel should flow steadily, like a bathroom faucet on half

What weak flow indicates:

| Symptom | Likely Cause |

|---|---|

| Trickle instead of stream | Clogged fuel filter or tank vent |

| No flow when hot, flow when cold | Vapor lock in fuel pump |

| Intermittent spurts | Failing fuel pump or stuck float |

On EFI bikes, fuel pressure should meet spec (typically 40-50 PSI). Low pressure when hot points to a dying fuel pump.

For mixture-related issues on carbureted bikes, see our guide on adjusting air-fuel mixture.

Compression Issues from Heat Expansion

Metal expands when heated. On motorcycles, this expansion changes critical tolerances.

Valve Clearance Too Tight

Valve clearances set when cold become tighter when hot. Valves that don’t fully close can’t build compression.

How to check:

- Engine must be completely cold (ideally overnight)

- Remove valve cover

- Rotate engine to TDC on compression stroke

- Slide feeler gauges between valve stem and rocker arm

- Compare to service manual specs (typically 0.003-0.006 inches intake, 0.005-0.008 exhaust)

If clearances are tight (gauges don’t fit):

- Valves stay slightly open when hot

- Compression escapes during cranking

- Hot starts become impossible despite perfect spark and fuel

Adjusting requires shims (shim-under-bucket designs) or screw adjusters (older bikes). This is precision work. Follow your manual exactly.

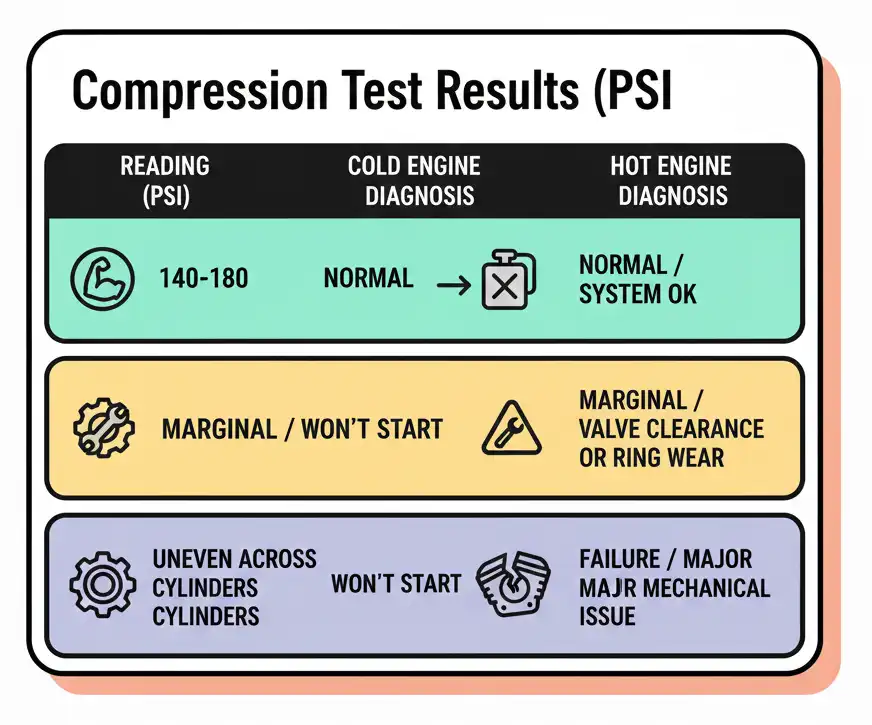

Compression Test Results

| Reading (PSI) | Cold Engine | Hot Engine | Diagnosis |

|---|---|---|---|

| 140-180 | Normal | Normal | System OK |

| 120-140 | Marginal | Won’t start | Valve clearance or ring wear |

| Below 100 | Won’t start | Won’t start | Major mechanical failure |

| Uneven across cylinders | Suspect | Failure | Head gasket or valve damage |

If your engine dies when applying throttle, low compression might be starving power under load.

Starter Motor Heat Soak

The starter motor itself can be a culprit. Heat builds electrical resistance in the windings and causes mechanical binding.

Symptoms of starter failure:

- Single slow “clunk” when hot (versus rapid cranking when cold)

- Starter spins but doesn’t engage flywheel

- Heavy battery drain during start attempts

- Clicking from starter relay

The touch test: After a failed hot start, carefully feel the starter motor body. If it’s significantly hotter than surrounding engine components, the starter is drawing excessive current or binding internally.

Bench test procedure:

- Remove starter

- Connect directly to battery with jumper cables

- Starter should spin freely and rapidly

- If it hesitates, makes grinding noises, or feels “sticky,” replacement is needed

Rebuilt starters often fail sooner than OEM replacements. Buy quality parts.

Temperature Sensors Lying to ECU

Fuel-injected bikes rely on sensors to determine how much fuel to inject. A faulty coolant temperature sensor sends wrong data, causing the ECU to flood a hot engine thinking it’s cold.

How temperature sensor failure presents:

- Hard start when hot, perfect start when cold

- Rich fuel smell after riding

- Black smoke from exhaust

- Check engine light (sometimes, not always)

Testing the sensor:

- Locate the coolant temperature sensor (usually near thermostat housing)

- Disconnect sensor connector

- Measure resistance with multimeter

- Compare to temperature-resistance chart in service manual

- Sensor should show low resistance when hot, high resistance when cold

A sensor reading the same resistance at all temperatures is failed. Replacement sensors are inexpensive but must match your bike’s specifications exactly.

Don’t Overlook the Kill Switch

Before diagnosing complex failures, check your engine cut-off switch. Heat causes plastic switches to expand, sometimes preventing full return to the “run” position.

The symptoms mimic serious problems:

- Engine cranks but won’t fire

- All other electrical functions work normally

- No spark at plugs

Toggle the kill switch firmly several times. Clean the contacts with electrical contact cleaner if accessible. A $15 switch replacement beats hours of misdiagnosis.

Diagnostic Flowchart for Hot-Start Failure

Step 1: Check battery voltage

- Below 12.4V? Replace battery

- Above 12.4V? Continue to Step 2

Step 2: Test for spark

- Remove plug, ground to engine, crank

- No spark or weak orange spark? Check coils, CDI, connections

- Good blue spark? Continue to Step 3

Step 3: Verify fuel delivery

- Disconnect fuel line, check flow

- No flow? Check filter, pump, tank vent

- Good flow? Continue to Step 4

Step 4: Test compression

- Use compression tester

- Below 100 PSI or uneven? Check valve clearances

- Good compression? Check temperature sensors

Step 5: Check kill switch

- Toggle switch, clean contacts

- Still no start? Recheck Steps 1-4 methodically

Prevention: Stop Hot-Start Problems Before They Start

Battery maintenance:

- Test voltage monthly

- Clean terminals every oil change

- Replace every 3-4 years regardless of apparent condition

- Use battery tender when bike sits more than a week

Fuel system care:

- Replace fuel filter per manual schedule (typically 12,000 miles)

- Use fuel stabilizer if bike sits unused

- Keep tank above half-full in summer heat

- Inspect fuel lines for cracks or heat damage annually

Ignition system:

- Replace spark plugs at recommended intervals (6,000-12,000 miles)

- Inspect plug wires for cracks or carbon tracking

- Test coil resistance every 10,000 miles

- Carry spare CDI on older bikes

Valve clearances:

- Check every 6,000-12,000 miles per manual

- Adjust if clearances are outside spec

- Don’t skip this maintenance—tight valves cause expensive damage

Cooling system (liquid-cooled bikes):

- Flush coolant every two years

- Inspect hoses for soft spots or cracks

- Verify radiator fan operation

- Keep fins clean and unrestricted

Understanding how long rides at high RPM affect your engine helps you maintain proper operating temperatures.

When to Call a Mechanic

Some hot-start issues require professional diagnosis:

Advanced electrical problems:

- Intermittent failures that don’t follow patterns

- Multiple system failures simultaneously

- Melted wiring or burned connectors

- Check engine codes requiring scan tools

Engine mechanical issues:

- Low compression across all cylinders

- Metal shavings in oil

- Unusual engine noises (knocking, rattling)

- Oil consumption above 1 quart per 1,000 miles

Fuel injection mapping:

- Aftermarket performance modifications

- Persistent rich or lean running

- Multiple failed component replacements without resolution

Professional diagnosis costs $80-150 per hour but saves money versus replacing parts randomly.

FAQs About Motorcycle Won’t Start When Engine Is Hot

How do I know if vapor lock is causing my hot-start issue?

If your bike starts immediately when cold but refuses to start after riding, and waiting 20-30 minutes solves it, vapor lock is likely. A strong fuel smell when opening the tank indicates pressure buildup.

Can I damage my engine trying to start it when hot?

Repeated start attempts with a flooded engine can wash oil from cylinder walls, accelerating wear. Limit attempts to 5-second bursts with 30-second rests between tries to avoid starter overheating.

Why does my bike start fine with a jump but not on its own battery?

Your battery lacks capacity for hot starts. Replace it even if it tests “good” at rest, voltage under load reveals the real condition.

Should I open the throttle when starting a hot engine?

On carbureted bikes with flooding, hold throttle wide open to clear excess fuel. On fuel-injected bikes, leave throttle closed. The ECU controls fuel delivery automatically.

How tight should valve clearances be when hot versus cold?

Always measure when cold per manual specs. Hot clearances are tighter due to expansion, but trying to measure hot risks inaccurate readings and burned fingers.

Will adding an aftermarket fuel pump fix vapor lock issues?

On carbureted bikes, a low-pressure electric pump before the mechanical pump can help. On EFI bikes, the OEM pump should handle heat; fix routing and shielding instead.