You’ve been cruising on the highway for three hours straight. Your tachometer hovers at 7,500 RPM, and a nagging question creeps into your head: Is this sustained screaming killing my engine?

Here’s the straight answer: No, long rides at high RPM won’t immediately damage a modern, well-maintained motorcycle engine if you stay below redline.

Modern engines, especially liquid-cooled designs, handle sustained operation at 75-80% of maximum RPM for hours. However, this riding style accelerates component wear on piston rings and bearings by 30-45% and degrades engine oil significantly faster than city riding due to shear forces breaking down viscosity modifiers.

While your engine won’t explode, treating a highway cruiser like a race bike requires specific maintenance adjustments. Understanding what happens inside your crankcase at sustained high revs helps you ride smarter and extend engine life.

🎯 Key Takeaways

- The Verdict: No immediate damage, but it accelerates component wear by 30–45%.

- The Real Killer: Mechanical oil shear, not just heat, thins your lubricant.

- New Rule: If you cruise at 70%+ of redline, cut your oil change intervals in half.

- Pro Tip: Drop your RPMs for 2 minutes every half hour to shed “heat soak.”

- Do Long Rides at High RPM Damage the Engine?

- What RPM is Considered “High” for Different Types of Motorcycles?

- Mitigating High RPM Risks Through Bike Engine Design

- Maintenance Practices for High RPM Damage Control

- General guidelines for riders

- FAQs: Do Long Rides at High RPM Damage the Motorcycle Engine?

What Actually Happens Inside Your Engine at High RPM

Three mechanical processes accelerate when you hold the throttle open for hours.

Piston ring wear increases exponentially. At sustained high RPM, camshaft wear rates jump by 50%, and piston rings experience similar stress.

Racing teams replace pistons every 15-30 hours for this reason. The rings simply can’t maintain proper sealing under continuous high-speed operation.

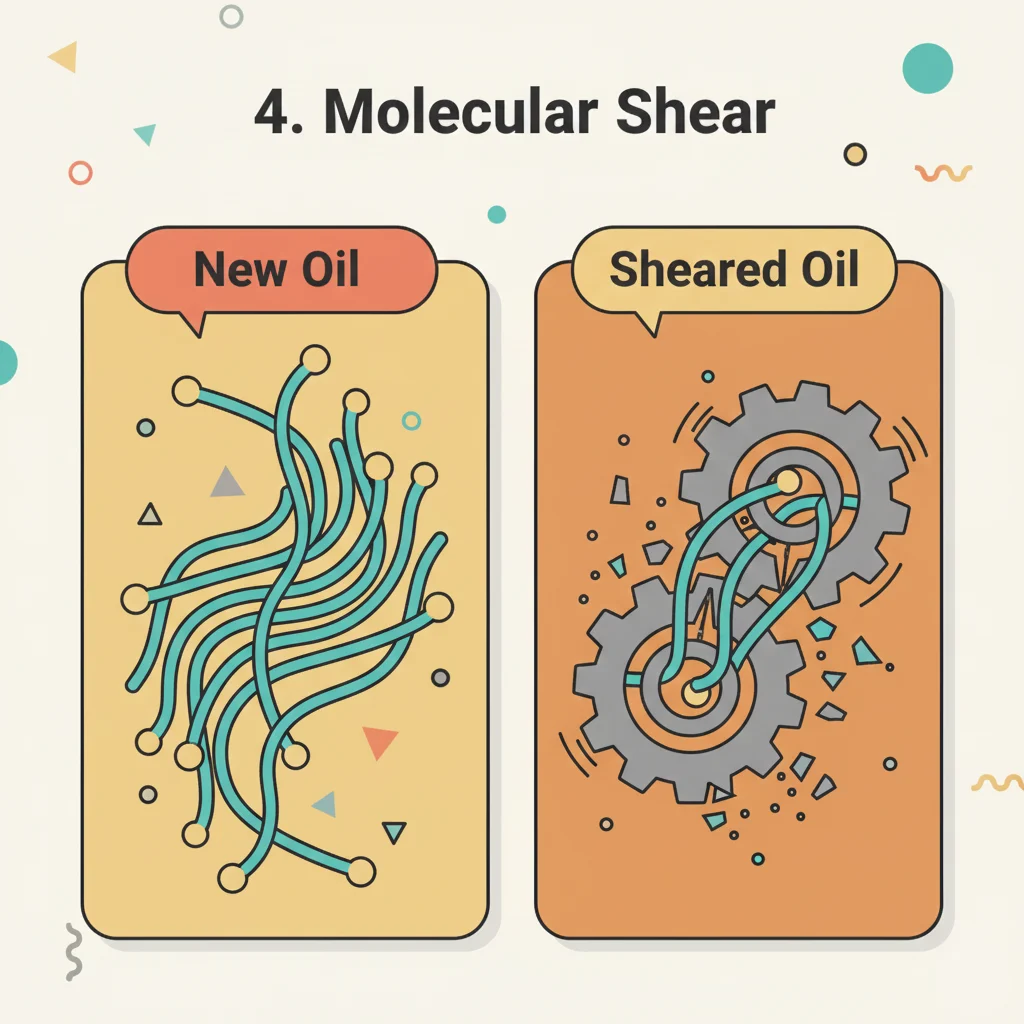

Oil breaks down through mechanical shear. High RPM subjects oils to higher loading and shear forces, which rupture the lubricant film and reduce viscosity, increasing wear.

The viscosity index improvers that keep your oil thick at temperature literally get torn apart by transmission gears and bearing surfaces. This happens faster than thermal breakdown. Your oil thins from mechanical action, not just heat.

Heat accumulates beyond cooling system capacity. Understanding how hot motorcycle engines run helps explain why sustained high RPM stresses cooling systems.

Extreme high temperatures exceed 150°C in performance engines. Without periodic RPM reduction, heat-soaked components expand beyond design tolerances.

Valve guides, piston rings, and bearing clearances all operate outside their optimal range, accelerating wear patterns.

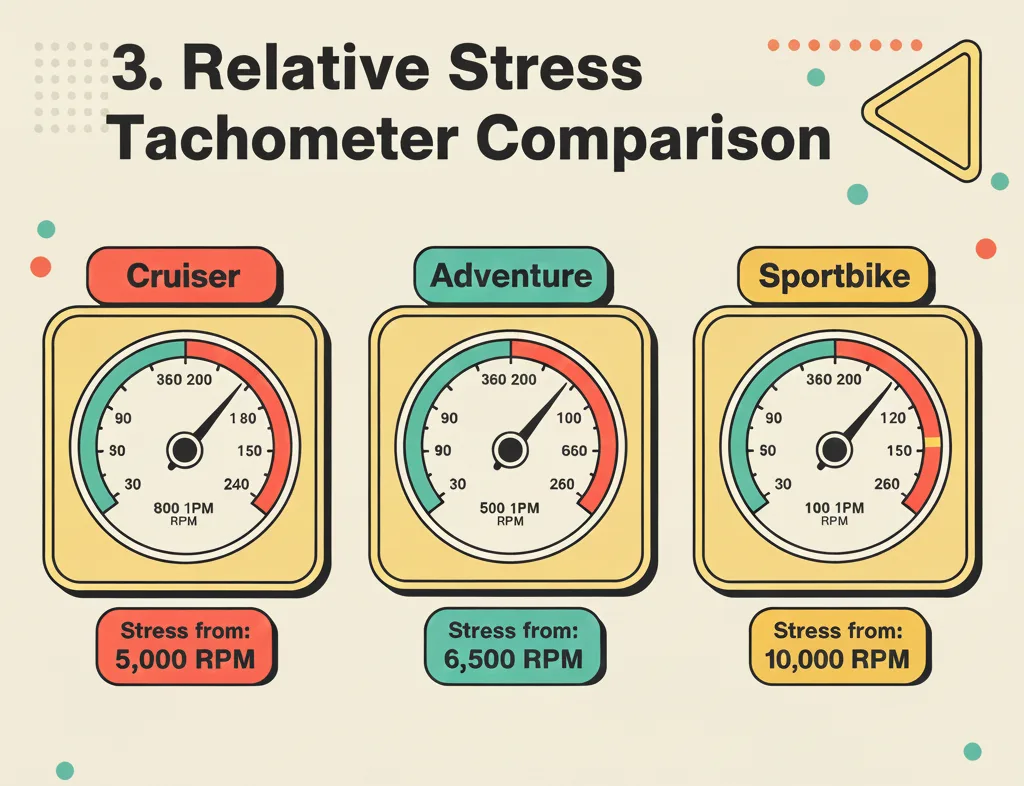

Defining “High RPM” for Different Motorcycle Types

What counts as high RPM varies dramatically by engine design. Understanding different motorcycle engine types explains why a cruiser screaming at 6,000 RPM experiences more stress than a sportbike purring at 8,000 RPM, engine displacement and RPM capacity directly correlate with stroke length and piston speed.

| Motorcycle Type | Normal Operating Range | High RPM Threshold |

|---|---|---|

| Cruiser/Touring | 2,000-4,000 RPM | Above 5,000 RPM |

| Standard/Naked | 3,000-6,000 RPM | Above 6,500 RPM |

| Sport Bike | 6,000-9,000 RPM | Above 8,000 RPM |

| Supersport | 8,000-12,000 RPM | Above 10,000 RPM |

| Adventure/Dual Sport | 3,000-6,000 RPM | Above 6,500 RPM |

Track bikes average around 10K+ RPM and don’t sustain damage with proper maintenance. The difference lies in engine design. Oversquare engines with larger bores and shorter strokes handle high RPM better than undersquare designs optimized for low-end torque.

Your bike’s powerband tells you where it wants to operate. Engines designed for lower RPM ranges should operate in that range, pushing beyond wastes fuel and shortens engine life without performance gains.

How Modern Engine Design Mitigates High RPM Damage

Engineers build performance motorcycles to handle sustained high revs through specific technologies.

Forged pistons with optimized geometry. Forged aluminum pistons weigh 20-30% less than cast equivalents while handling higher cylinder pressures. Forging creates better-aligned grain flow and higher tensile strength, letting pistons survive repeated acceleration forces without fracturing.

Advanced surface coatings reduce friction. Nitride-coated piston rings, DLC (diamond-like carbon) coatings on pins, and hard-anodized cylinder walls all reduce metal-to-metal contact. These surfaces handle higher temperatures and friction with minimal material transfer.

Pressurized oiling systems with targeted jets. Performance engines spray oil directly onto piston undersides and onto camshaft lobes under pressure. This targeted cooling prevents hot spots that cause piston crown damage and valve guide wear.

Gear-driven camshafts eliminate timing chain stretch. Racing engines use gear drives because chains stretch under sustained high RPM, throwing off valve timing. Gear drives maintain precise timing regardless of RPM or duration.

One performance builder noted their cylinder temperature remained stable at 110°C under continuous high RPM operation with proper synthetic oil, reducing piston ring wear by 60%.

Oil Degradation at High RPM: The Hidden Killer

Oil failure causes more high-RPM damage than mechanical stress.

Motorcycle engines produce more horsepower per cubic inch than automobiles and operate with higher compression ratios, placing greater demands on oil to fight wear and chemical breakdown. At sustained high RPM, three degradation processes accelerate:

Mechanical shear from transmission gears. Gear sets in motorcycle transmissions lead to shear-induced viscosity loss. Unlike cars with separate transmission oil, motorcycles use shared engine/transmission lubrication. Every gear mesh tears apart long-chain viscosity modifiers, permanently thinning the oil.

Thermal breakdown from combustion heat. Oil temperatures in air-cooled engines can exceed 300°F at sustained highway speeds. Rear cylinder temperatures can exceed 420°F in V-twin engines, directly heating oil as it splashes off internal components.

Oxidation from continuous exposure to combustion byproducts. Blow-by gases introduce combustion acids and carbon particles into your crankcase. At high RPM, increased blow-by accelerates oil contamination. One racer mentioned changing oil every 20 hours during track use, at 10,000 RPM average, that’s 12 million engine cycles per oil change.

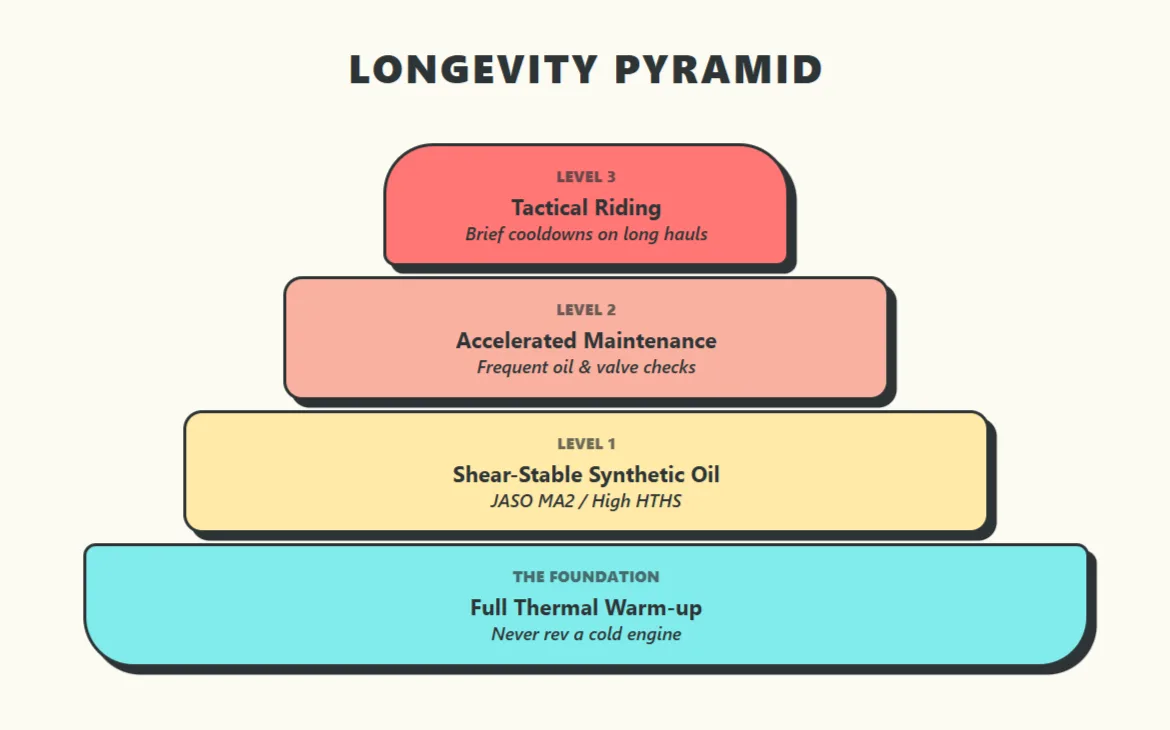

Solution: Use JASO MA or MA2 certified oils with high shear stability ratings. Motorcycle oils with published HTHS (High Temperature High Shear) ratings above 6.0 maintain viscosity under extreme stress. Synthetic esters resist shear better than mineral-based oils because their molecular structure doesn’t rely on viscosity modifiers.

Maintenance Schedule Adjustments for High RPM Riding

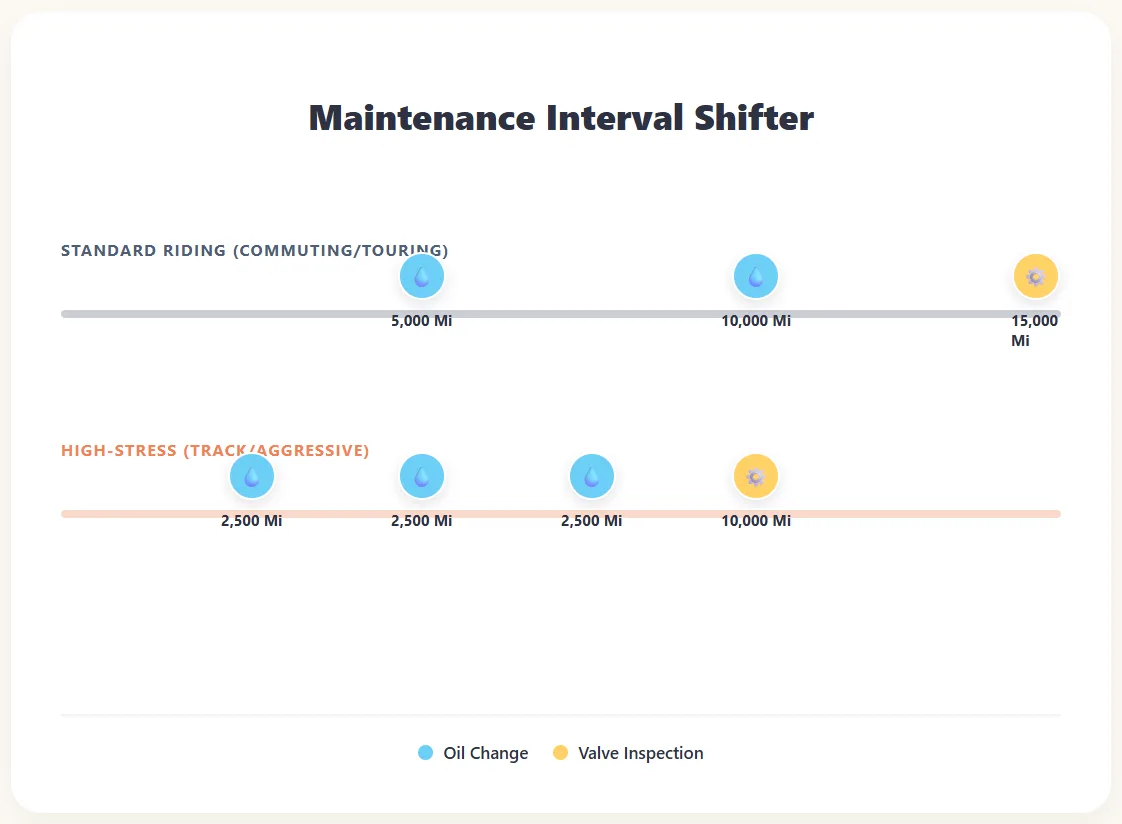

If you regularly cruise above 70% of redline, standard service intervals don’t apply.

Shorten oil change intervals by 30-50%. The manufacturer recommends 5,000-mile changes for typical riding. If you’re holding 7,000+ RPM for hours, change at 2,500-3,500 miles. Frequent oil changes remove heat and contaminants before they cause damage.

Inspect valve clearances every 10,000 miles. High RPM accelerates valve train wear. Tight clearances cause valve float—where valves don’t fully close, leading to burned valves and lost compression. Valve contact with pistons can occur due to valve float from excessive RPM.

Monitor coolant condition and flush regularly. Coolant breaks down from sustained high temperatures. Old coolant loses corrosion inhibitors and boils at lower temperatures. Flush every two years if you ride hard, regardless of mileage.

Check piston ring health through compression testing. Compare compression test readings with specifications, variations indicate ring wear. Test every 15,000 miles if you frequently run high RPM. Catching ring wear early prevents catastrophic piston seizure.

Watch for abnormal sounds indicating bearing wear. Knocking from the bottom end, ticking from the top end, or rattling from the transmission all signal accelerated wear. Metal expands with heat—thrashing a cold engine leads to premature wear on piston rings and valve guides.

Safe High RPM Riding Practices

You can ride hard without shortening engine life by following specific protocols.

Always warm up completely before sustained high RPM. Oil needs to reach operating temperature to flow properly. Cold oil can’t protect bearings and cam surfaces. Wait until the engine reaches 180°F (indicated by temperature gauge or 5+ minutes of riding) before holding high revs.

Stay within the powerband, not the redline. Most engines make peak power 500-1,000 RPM below redline. Operating an engine in its designed RPM range maximizes efficiency. Check your owner’s manual for peak power RPM and cruise there, redlining the engine constantly shortens engine life even if the limiter prevents valve float.

Drop RPM every 30 minutes during extended high-speed runs. Reduce throttle for 2-3 minutes every half hour. This lets components cool slightly and allows fresh oil to circulate through heat-soaked areas. Using engine braking at high RPM during these cooldown periods helps manage speed while reducing stress.

Avoid lugging the engine under heavy load. Don’t cruise in top gear at 3,000 RPM then accelerate hard. Lugging an engine causes detonation, damaging internal components. Downshift before accelerating—brief high RPM during acceleration causes less wear than sustained low RPM under heavy load.

Listen for changes in engine character. New sounds — ticking, knocking, rattling — indicate problems developing. Stop immediately and investigate rather than riding through concerning noises.

When High RPM Actually Causes Immediate Damage

Certain conditions turn sustained high RPM from accelerated wear into catastrophic failure.

Running low on oil. Modern engines use oil jets for piston cooling. Low oil level means pistons overheat, rings lose tension, and seizure occurs. Check oil before every ride if you run hard.

Incorrect fuel mixture from carburetor problems. Lean conditions cause detonation, uncontrolled combustion that hammers pistons. Engines operated with lean mixture at full throttle see abnormally high combustion temperatures causing piston crown erosion. If your bike has fuel leaking from the carburetor or incorrect air-fuel mixture, fix these before sustained high RPM riding.

Cooling system failures. Overheating causes oil to break down instantly and metal components to seize. Watch your temperature gauge. If it climbs above normal during sustained high RPM, back off immediately. For bikes experiencing engine stalls when hot, vapor lock or cooling problems need resolution first.

Ignoring warning signs. Small problems become catastrophic under sustained stress. That slight ticking noise or minor oil consumption won’t stay minor at 8,000 RPM. Address engine problems during acceleration before they escalate.

Real-World High RPM Longevity Examples

Modern motorcycles demonstrate impressive durability when properly maintained.

Sport bikes routinely reach 50,000+ miles with original engines despite frequent high RPM use.

The key: owners follow aggressive maintenance schedules, use premium synthetic oils, and warm up properly.

Touring bikes covering 100,000+ miles typically see lower peak RPM but longer sustained runs. These engines last because they operate in their design range, not pushing limits but maintaining steady, efficient RPM.

Track bikes experience more demanding conditions yet last when properly maintained. Professional teams rebuild engines not because components fail but because they’ve reached safe service life, preventing failure rather than reacting to it.

Small displacement bikes designed for commuting suffer most from sustained high RPM because they weren’t engineered for it. Small displacement motorcycles aren’t intended as highway bikes, they’re designed for town use at lower speeds. Pushing them to highway speeds creates stress their components can’t handle long-term.

Understanding what is engine braking helps because aggressive downshifts create RPM spikes similar to sustained high-RPM riding, both stress components but in different ways.

Oil Specification Requirements for High RPM Protection

Not all motorcycle oils handle sustained high RPM equally.

JASO MA2 certification ensures wet clutch compatibility. Motorcycle oils need compatibility with clutches while providing adequate lubrication and containing higher chemical dispersants to trap dirt. Never use automotive oil in motorcycles, friction modifiers destroy wet clutches.

High HTHS ratings indicate shear resistance. Look for oils with HTHS above 4.5 cP minimum, preferably above 6.0 cP for aggressive riding. Oils meeting top shear stability requirements maintain protection under sustained stress.

Synthetic ester base stocks outperform mineral oils. PAO and ester base oils provide 200% improvement in high-temperature stability. While more expensive, they resist breakdown from heat and shear, extending drain intervals and protecting better.

Appropriate viscosity for operating temperatures. 10W-40 works for most conditions. Hot climates or air-cooled engines benefit from 15W-50 or 20W-50. Colder climates allow 5W-40. The right viscosity maintains film strength at operating temperature.

Popular choices among high-RPM riders include full synthetic options from Motul, Mobil 1 Racing, Redline, and Amsoil. These brands publish detailed specifications showing shear stability and temperature resistance.

FAQs: Do Long Rides at High RPM Damage the Motorcycle Engine?

Does high RPM burn more oil?

Yes. Higher piston speeds increase the volume of oil mist in the crankcase, which is often vented into the airbox and burned. Check oil levels at every fuel stop on long trips.

Is it better to be in a high gear at low RPM or lower gear at high RPM?

Generally, a lower gear at moderate-to-high RPM is better than “lugging” in top gear. Lugging places massive stress on the crankshaft bearings, while high RPM mostly stresses the valvetrain and rings.

Can I ride at the redline?

Briefly, yes. Sustained riding at the redline is dangerous. It risks valve float (where valves don’t close fast enough) and piston-to-valve contact. Keep it 1,000 RPM below redline for safety.

Do air-cooled engines suffer more at high RPM riding?

Yes. They rely on airflow. If you are stuck in traffic revving high, or riding fast with a tailwind, they can overheat. Liquid-cooled engines are much more tolerant of sustained high RPM.

Does high RPM clean the engine?

Partially. The “Italian Tune-up” (running hard to burn carbon) has merit. High heat helps burn off carbon deposits on valves and spark plugs that accumulate during slow city riding.

Can I use car oil in my motorcycle for high-RPM riding?

Never. Car oils contain friction modifiers incompatible with motorcycle wet clutches and won’t survive extreme shearing from transmission gears. Always use JASO-certified motorcycle oil.

How often should I change oil if I ride aggressively?

Reduce standard intervals by 40-50%. If the manual specifies 5,000 miles, change at 2,500-3,000 miles. Aggressive riding requires oil changes to remove accumulated heat and contaminants.