Your motorcycle engine cuts out mid-ride because fuel delivery fails, spark weakens, air intake clogs, or the engine overheats. Most cut-outs trace back to clogged fuel filters (restricts flow), worn spark plugs (no ignition), dirty air filters (suffocates combustion), blocked fuel cap vents (creates vacuum), loose electrical connections (interrupts power), or overheating (triggers safety shutdown).

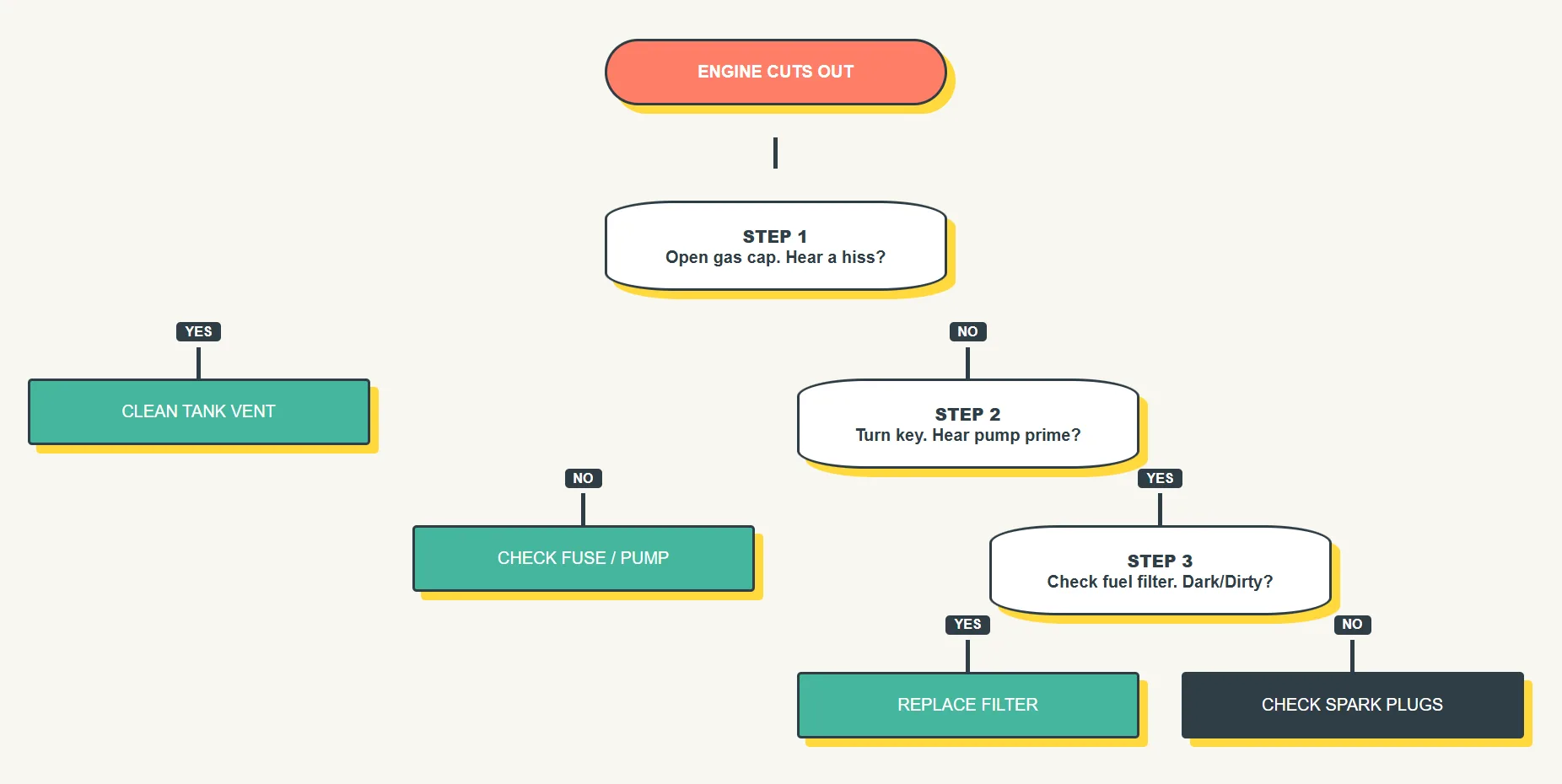

Start troubleshooting with fuel — check the tank level, tap the gas cap for a “whoosh” sound, and inspect the fuel filter for debris. Then test spark by removing a plug and cranking the engine. If spark looks weak or absent, replace plugs and check battery voltage (should read 12.6V). Finally, examine the air filter and look for vacuum leaks around intake boots.

This guide discusses all these reasons and fixes in detail.

🎯 Key Takeaways

- Most Common Culprit: Fuel delivery issues (clogged filters or blocked gas cap vents) cause 60% of random cut-outs.

- The “Hiss” Test: If your bike stalls, open the gas cap. A loud “whoosh” means your vent is blocked, creating a vacuum.

- Electrical Gremlins: A battery reading below 12.4V or a loose terminal can kill the engine mid-ride due to vibration.

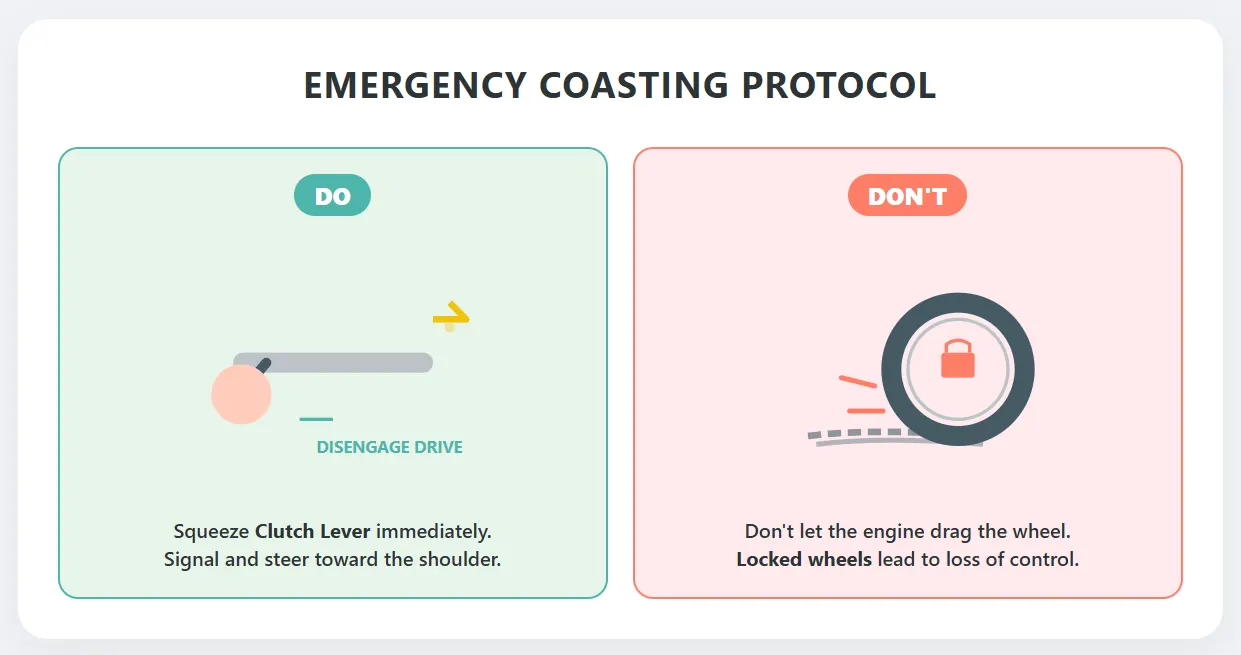

- Safety First: If the engine cuts at speed, pull the clutch immediately to prevent rear-wheel lockup and coast to the shoulder.

- The Pro Fix: Always troubleshoot in this order: Fuel → Spark → Air → Electrical.

Top Causes Behind Engine Cut-Outs

1. Fuel Delivery Failures Starve Your Engine

Fuel problems trigger most engine cut-outs. Your bike needs consistent fuel pressure from tank to combustion chamber because any blockage kills the engine.

Empty or Low Fuel Tank

Gauges lie. Your fuel level drops lower than the sensor reads, starving the engine mid-ride. Always fill up before long trips.

Clogged Fuel Filter or Line

Old fuel leaves residue. Dirt, rust, and varnish block the filter or line. Check your filter—if it looks brown or black instead of clean, replace it immediately.

Contaminated Fuel

Water or debris sneaks into your tank from bad gas stations or condensation. Contaminated fuel won’t burn properly. Drain the tank if you see black goo or smell something off.

Faulty Fuel Pump

Electric pumps wear out, especially when running hot. Listen when you turn the key—you should hear the pump prime for 2-3 seconds. No sound means the pump died. Test fuel pressure with a gauge (check your manual for specs—usually 40-50 PSI for fuel-injected bikes).

Blocked Fuel Cap Vent

Your tank needs air to replace fuel as it flows out. A blocked vent creates a vacuum that stops fuel flow. Pop your gas cap after riding. If you hear a loud hiss, the vent was clogged. Clean your carburetor to prevent fuel blockage issues.

| Fuel Issue | Symptom | Quick Fix |

|---|---|---|

| Empty tank | Sudden shutdown | Fill with fresh fuel |

| Clogged filter | Sputters under load | Replace fuel filter |

| Bad pump | Won’t prime | Test pump voltage, replace if needed |

| Blocked vent | Stalls after 10-15 min | Clean or replace fuel cap |

2. Ignition System Problems Kill Spark Instantly

No spark equals no combustion. Your ignition system delivers high voltage to spark plugs. When it fails, the engine dies without warning.

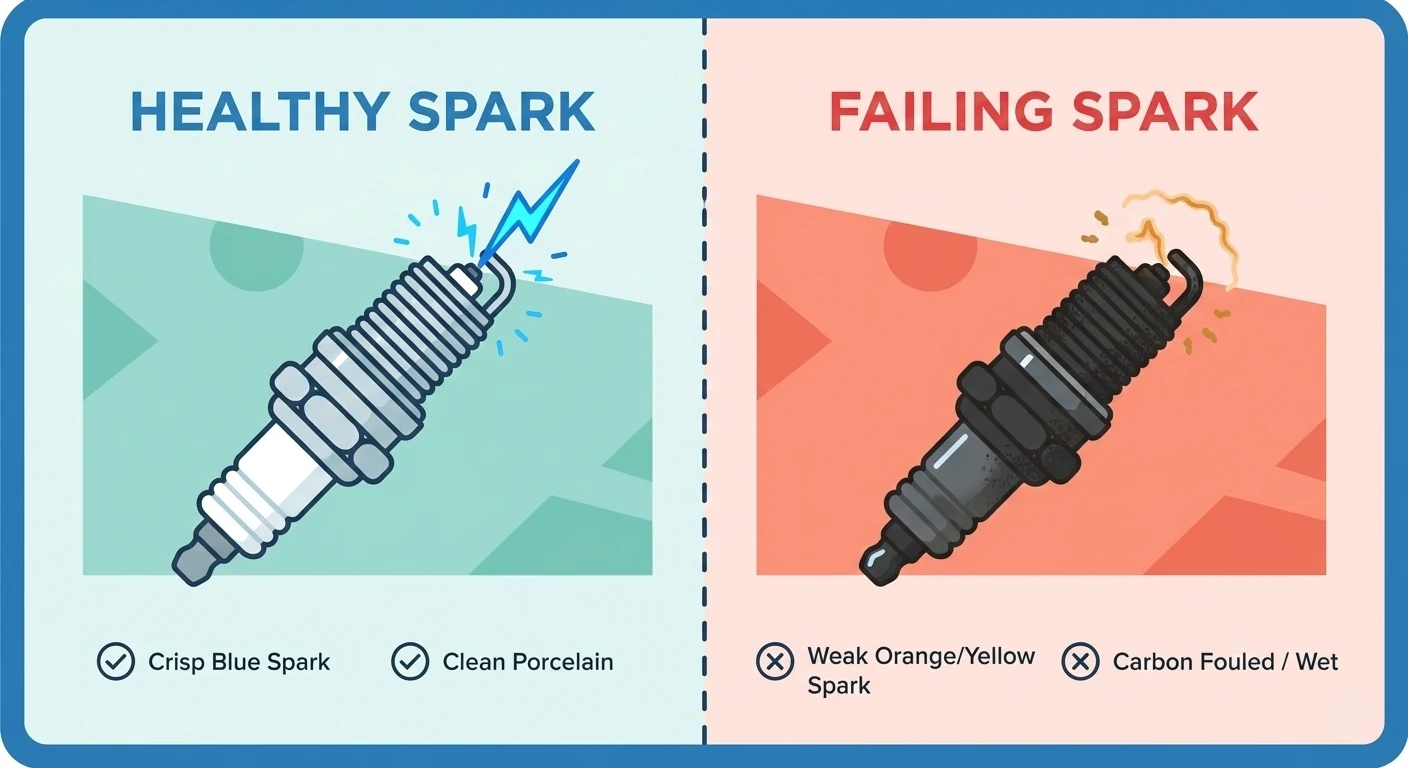

Worn Spark Plugs or Wires

Plugs wear out after 10,000-20,000 miles. Electrodes erode, gaps widen, and carbon builds up. Pull your plugs. If they’re black, oily, or the gap exceeds 0.035 inches, replace them. Cracked wires leak voltage before it reaches the plug.

Weak or Dead Battery

Modern fuel-injected bikes need 12+ volts to run fuel pumps and ignition. Low voltage (under 12.4V) can’t support these systems. Test with a multimeter — 12.6V when off, 13.5-14.5V when running. A dying battery flickers dash lights before the engine quits.

Loose Connections or Corrosion

Vibration shakes connectors loose over time. Green or white corrosion around terminals blocks current flow. Wiggle each wire connector while the engine runs. If the bike stumbles, tighten or clean that connection. Apply dielectric grease to protect from moisture.

Failed Sensors or ECU

Your bike’s computer relies on sensors (TPS, crank position, MAF) to control fuel and spark timing. When sensors fail, they send bad data and the ECU shuts everything down. Modern bikes store fault codes. Scan them with an OBD-II reader to pinpoint which sensor died. If your engine dies when throttle is applied, suspect the TPS.

Fix checklist:

- Replace spark plugs every season or per manual

- Charge battery to 12.6V minimum

- Clean all connectors with contact cleaner

- Scan for fault codes if check engine light appears

- Test ignition coil resistance (typically 5-15k ohms)

3. Restricted Airflow Chokes Combustion

Engines need precise air-fuel ratios (14.7:1 for gasoline). Too little air creates a rich mixture that won’t ignite properly. Too much air (from leaks) leans out the mixture and causes misfires.

Clogged Air Filter

Dirt accumulates on the filter element over thousands of miles. Restricted airflow drops power and causes the engine to stumble or stall, especially under acceleration. Pull your filter. If you can’t see light through it, replace it. Most bikes need new filters every 6,000-12,000 miles.

Vacuum Leaks in Intake System

Cracked rubber boots, loose clamps, or damaged gaskets let unmeasured air enter the engine. This leans out the mixture and makes idle rough or unstable. Spray carb cleaner around intake boots while the engine idles. If RPMs jump, you found the leak.

Unsynced Throttle Bodies (Multi-Cylinder Bikes)

Each cylinder needs equal airflow. When throttle bodies fall out of sync, one cylinder gets too much air while another starves. The engine shakes, idles rough, and may stall. Sync requires a vacuum gauge tool and patience. Follow your service manual’s procedure.

Action steps:

- Inspect air filter monthly

- Replace cracked intake boots immediately

- Tighten all clamp connections

- Sync throttle bodies every 12,000 miles

4. Overheating and Exhaust Blockage Shut Down the Engine

Heat management protects your engine from self-destruction. Most modern bikes monitor coolant temperature and cut power when overheating occurs.

Engine Overheating Triggers Safety Shutoff

Low coolant, broken radiator fans, or blocked cooling fins cause overheating. Watch your temp gauge. If it climbs into the red zone, the ECU may shut down the engine to prevent damage. Check coolant level when cold, inspect radiator for leaks, and listen for fan operation when the engine warms up. Old oil loses viscosity and can’t cool internal parts, so change it every 3,000-5,000 miles. If your bike won’t start when the engine is hot, overheating might be the culprit.

Blocked Exhaust Creates Backpressure

Clogged mufflers or collapsed catalytic converters trap exhaust gases. Backpressure fights against the piston’s exhaust stroke, raising temperatures and choking power. Remove the exhaust and look inside. If you see honeycomb structure collapsed or heavy carbon buildup, replace it.

Maintenance checklist:

| System | Check Point | Frequency |

|---|---|---|

| Coolant | Level and color | Monthly |

| Radiator | Fins clear, no leaks | Every ride |

| Fan | Activates when hot | Each start |

| Oil | Level and condition | Weekly |

| Exhaust | No rattles or blockage | Every 6 months |

5. Mechanical Wear Disrupts Engine Timing

Your engine’s internal components must move in perfect rhythm. When timing slips or compression drops, the engine loses power and stalls.

Worn Timing Chain or Belt

Timing components stretch or wear after 20,000-40,000 miles (varies by bike). Stretched chains cause valves to open late or close early, disrupting combustion. Listen for rattling from the timing cover on startup. Replace chains per your manual’s schedule (most recommend every 25,000-30,000 miles).

Low Compression from Worn Valves or Rings

Compression should measure 120-180 PSI per cylinder (check your manual). Low compression means combustion gases escape past worn rings or improperly sealed valves. The engine struggles to start, idles rough, and lacks power. Perform a compression test with a gauge. Readings should vary less than 10% between cylinders.

Internal Engine Damage

Broken valves, damaged pistons, or seized bearings stop the engine instantly. You’ll hear knocking, grinding, or sudden silence. This requires professional diagnosis and often a complete rebuild. If you notice unusual engine noise when accelerating, investigate immediately before catastrophic failure occurs.

Clutch or Transmission Issues

A slipping clutch or sticky shift mechanism can stall the bike when you pull the clutch lever or downshift. Worn clutch plates don’t fully disengage, creating drag that kills the engine at low RPM. Adjust clutch cable free play (typically 2-3mm at the lever) and inspect plates for wear.

Fix priority:

- Replace timing components per service schedule

- Test compression annually

- Adjust valve clearances every 12,000 miles

- Replace clutch if it slips under load

Step-by-Step Diagnosis Process

Random guessing wastes time and money. Follow this systematic approach to find the actual problem.

Here’s a quick reference symptom and diagnosis table:

| If the engine dies… | The most likely cause is… | The “Quick Test” to try: |

| Immediately after refueling | Contaminated/Watered Gas | Drain a small amount of fuel into a glass; look for bubbles. |

| When it gets hot | Vapor Lock or Ignition Coil | Open gas cap to check venting; test coil resistance. |

| When hitting a bump | Loose Battery Terminal | Wiggle the battery leads; they should not move. |

| When coming to a stop | Idle Air Control / TPS | Check for “hunting” idle or carbon buildup in the throttle body. |

| In heavy rain | Short Circuit / Wet Plug Wire | Inspect plug caps for cracks; spray with WD-40 to displace water. |

Step 1: Document When Cut-Outs Happen

Before touching tools, note the conditions:

- Does it die right after refueling? (contaminated fuel)

- Only when hot? (vapor lock, overheating, or heat-related electrical failure)

- In rain or after washing? (water in electrics)

- At idle vs. acceleration? (fuel starvation or sensor issues)

Patterns reveal causes. Write down every detail.

Step 2: Check Fuel System First

Start with the easiest fixes:

- Tap the gas cap — A quiet “whoosh” confirms the vent works. Silence means it’s blocked.

- Verify fuel level — Don’t trust the gauge alone; visually confirm.

- Inspect the fuel filter — Brown, black, or slimy means replace it now.

- Squeeze fuel lines — They should feel firm, not brittle or soft.

- Listen for fuel pump — Turn the key to ON without starting. Hear humming for 2-3 seconds? Pump works.

Fix any fuel problems before moving forward.

Step 3: Test Spark Strength

Remove a spark plug, keep the wire attached, and ground the metal base against the engine. Crank the starter and watch for spark. It should be bright blue and consistent. Weak yellow spark or no spark means:

- Bad spark plugs (replace)

- Worn plug wires (replace)

- Failed ignition coil (test resistance with multimeter)

- Dead battery (charge or replace)

Step 4: Inspect Air Intake

Check the air filter — Dirty filters choke the engine. Replace if clogged.

Smell around intake boots — Strong fuel odor indicates vacuum leaks.

Spray test for leaks — With engine idling, spray carb cleaner near intake connections. RPM changes confirm leaks. Replace cracked boots and tighten clamps.

Step 5: Examine Electrical Connections

Turn the key and watch dashboard lights (flickering means voltage problems). Wiggle wire connectors one at a time while the engine runs. If the bike stumbles or stalls, you found a bad connection. Look for green corrosion on terminals and clean with contact spray.

Modern bikes with diagnostic ports can reveal fault codes using an OBD-II scanner. Codes like P0335 (crank sensor) or P0122 (TPS) point directly to the failed component.

Step 6: Monitor Cooling System

Watch the temperature gauge while riding. If it climbs too high, check:

- Coolant level (when cold) — Top off if low

- Radiator condition — Look for leaks or blocked fins

- Fan operation — Should activate when temp rises

- Oil quality — Old, thin oil can’t cool properly

Step 7: Perform Mechanical Tests (Last Resort)

If fuel, spark, air, electrical, and cooling all check out, dig deeper:

Compression test — Reveals internal engine health. Each cylinder should measure within 10% of the others.

Valve clearance check — Tight valves prevent proper sealing; loose valves make noise. Adjust per manual specs.

Listen for abnormal sounds — Knocking, ticking, or grinding signals internal damage.

Only investigate mechanical issues after ruling out simpler causes.

Prevent Cut-Outs with Regular Maintenance

Prevention beats repair. These quick checks take 15 minutes but save hours of roadside frustration.

Weekly checks:

- Fuel level and cap vent operation

- Battery voltage (12.6V or higher when off)

- Oil level and condition

- Unusual sounds or smells

Monthly maintenance:

- Clean or inspect air filter

- Check all fluid levels (coolant, brake, oil)

- Inspect fuel lines for cracks

- Test battery under load

- Look for loose electrical connections

Seasonal service:

- Replace spark plugs

- Change engine oil and filter

- Inspect/replace fuel filter

- Clean throttle body

- Check valve clearances

- Sync carburetors or throttle bodies

Warning signs to investigate immediately:

- Check engine light stays on

- Flickering dash lights or dim headlight

- Rough idle or hesitation

- Unusual ticking, knocking, or whining

- Fuel or coolant smells

- Difficulty starting when warm

Small problems grow into expensive repairs. Catch them early through consistent maintenance. For more help, check this guide on common motorcycle problems.

What to Do When Your Engine Cuts Out While Riding

Stay calm. Pull in the clutch immediately to prevent the bike from jerking or locking up. Shift to neutral if possible. Coast to the shoulder or a safe spot away from traffic. Don’t panic-brake. Maintain control and use momentum to reach safety.

Once stopped, wait 2-3 minutes before attempting restart. This allows overheated components to cool or vapor locks to clear. Turn the key to ON and listen for the fuel pump. If you hear it prime, try starting. If the engine fires but immediately dies, you likely have a fuel delivery or sensor issue.

If the bike won’t restart, check basics:

- Is the kill switch in the correct position?

- Is the kickstand up (many bikes have safety cutoffs)?

- Does the battery show voltage (lights and dash work)?

Understanding engine braking effects helps manage the bike when power cuts unexpectedly. Don’t do anything in hurry. Controlled coasting beats abrupt stops.

Bottom Line

Motorcycle engines cut out when fuel delivery fails, spark weakens, airflow restricts, or heat builds up. Start diagnosis with the fuel system (most common cause), then test spark, check air intake, and examine electrical connections.

Regular maintenance — clean filters, fresh fluids, tight connections — prevents most cut-outs. When problems occur mid-ride, stay calm, pull the clutch, and coast to safety before troubleshooting. Avoid over-revving the engine or extended high-RPM riding that stresses components and increases failure risk.

FAQs About Motorcycle Engine Keeps Cutting Out

Why does my motorcycle only cut out when warm or hot?

Heat expands metal parts and can expose weak connections, failing sensors, or vapor lock in fuel lines. A faulty TPS or coil often fails when hot. Check for gas leaking from carburetor due to heat expansion issues.

Can a dirty air filter cause my engine to stall?

Yes. Clogged filters restrict airflow, creating an overly rich mixture that won’t combust properly. The engine loses power and may stall, especially during acceleration or under load.

Will repeated stalling damage my motorcycle?

How do I know if my fuel pump is failing?

What causes stalling when I pull in the clutch?

Lean idle mixture, unsynced throttle bodies, or vacuum leaks commonly cause this. The engine can’t maintain RPM without throttle input. Adjust idle speed and check for choke system issues.

Does low battery voltage cause engine cut-outs?

Yes. Modern fuel-injected bikes need 12+ volts to run fuel pumps, injectors, and ignition. When voltage drops below 12V, these systems fail and the engine dies immediately.